I have been working on a way to measure thrust over time of my rockets for a while now

After a good friend of mine got me a 5kg load cell and alot of procrastinating I put it together

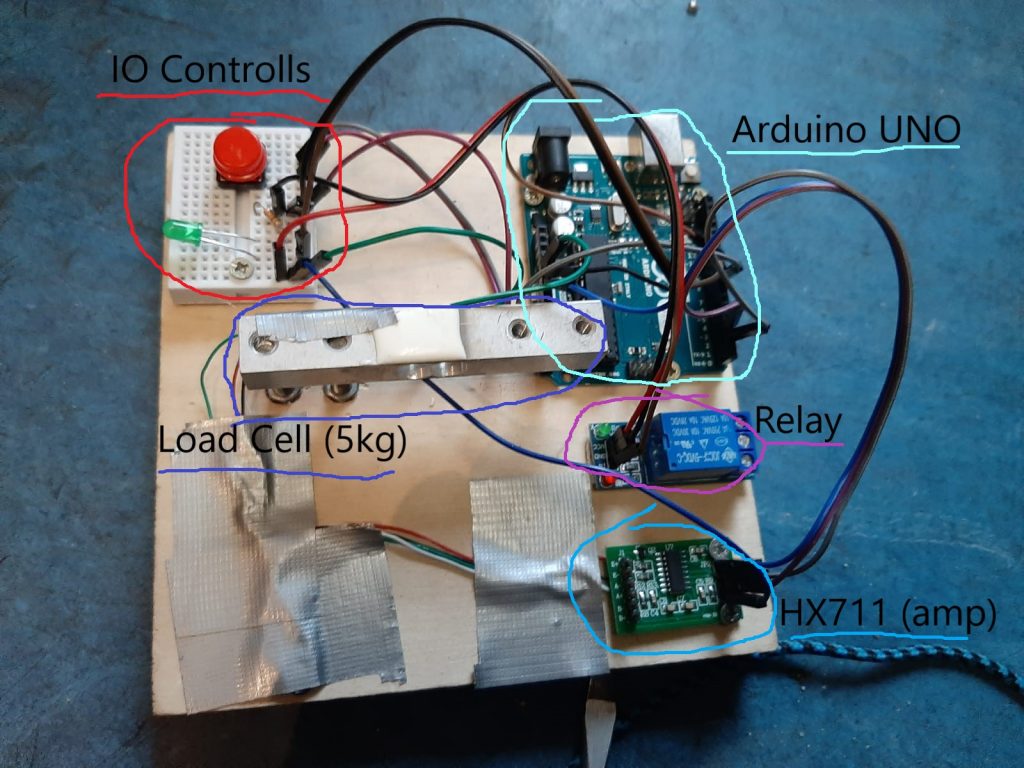

The STTS consists of the following components

- Load Cell (5kg, measures thrust)

- HX711 (Amplifier for hookup to the Arduino)

- Arduino UNO (For controlling the electronics and reading / sending the data to a laptop)

- Relay (For electrical ignition)

- Led and Button (For starting and warning)

When the Button is pressed a 10 second countdown starts (with the led blinking to signal this), after which the relay will be switched on for 10 seconds to allow ignition and measurements will be sent over serial indefinitely

If the button is pressed again during the countdown it will abort, requiring a reset of the Arduino to continue for safety reasons

If the button is pressed after the measurements have started, it will stop the measurements

All this is received over serial using Extra PuTTY which I chose since it allows logging to a file (essential to guarantee data recovery) and timestamps (something which standard PuTTY does not support)

(Turns out I was wrong and standard PuTTY does support data logging, so I have since switched back)

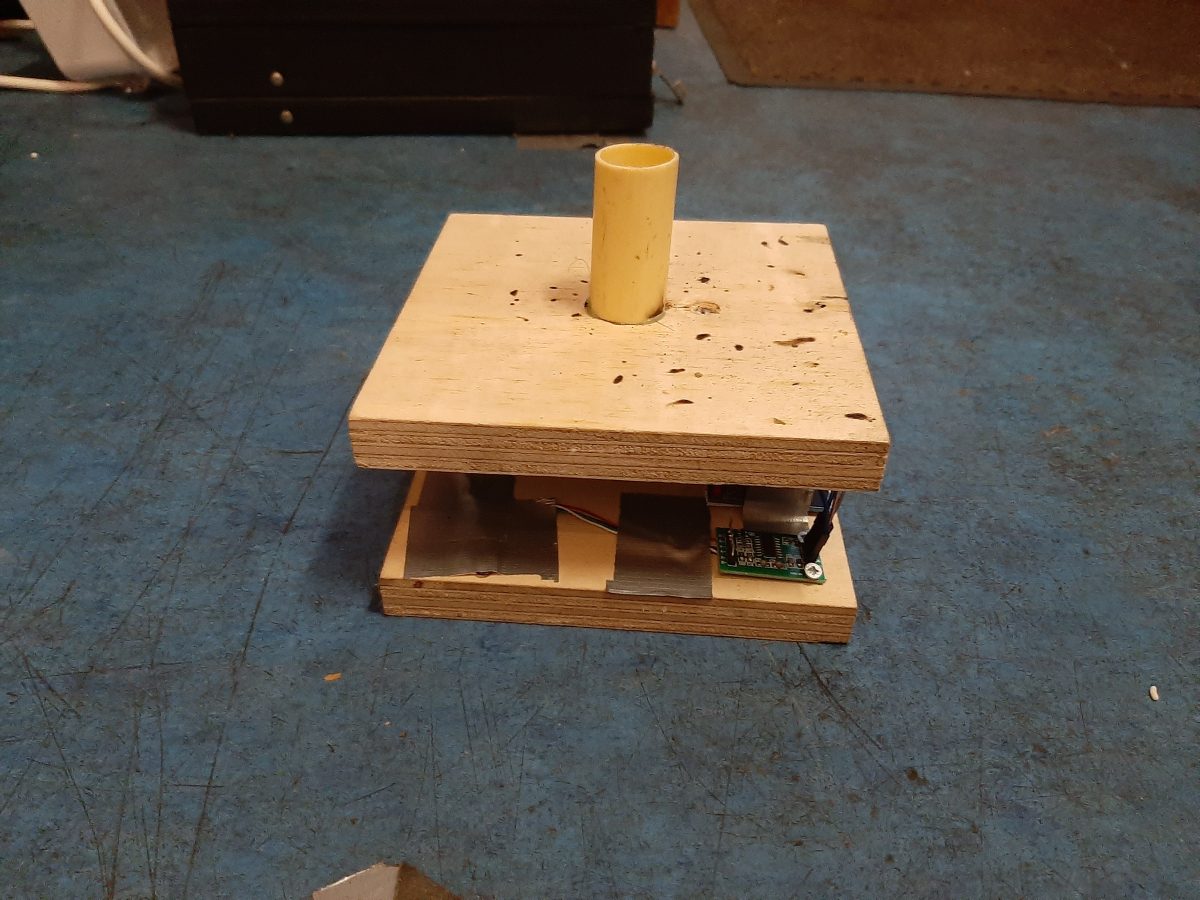

I have tested this setup with a leftover KNSB rocket motor which was 2 weeks old at this time, and stored in wrapping in a ammo crate to reduce ambient moisture absorption (spoiler, it did not work so well)

It was 30 grams (approx. 15 to 20 propellant) before being loaded into the tube at the top of the STTS, to stop it from accidentally taking off

After about 10 failed starts (and some tactical application of gunpowder) it ignited:

My conclusion on the rocket itself is that the fuel was probably damp from storage resulting in a slower burn time and decreased thrust, and the nozzle was not of optimal size resulting in less thrust

The burn itself lasted about 16-18 seconds, optimal burn time would be around 3-6 seconds

I also noted molten chunks of fuel (I am presuming un-reacted KNO3) getting pushed out of the nozzle, indicating the mix was not ideal either (moisture could also play a role in this)

Due to the slower burning and non optimal fuel the casing heated up and ruptured after thrust and pressure had depleted, resulting in alot of smoke and if in flight destruction of (part of) the rocket

As for the STTS, other than some minor burns on the base (expected) and a wobbly foundation (to be fixed) it performed well

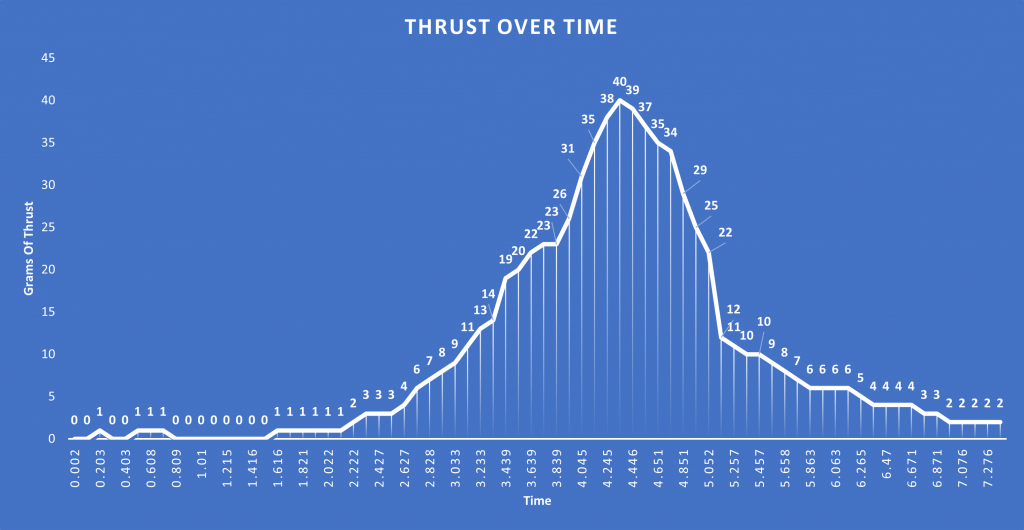

Here is the graph made from the extrapolated and parsed data

There are a few things to note here:

First of all I added 5 grams to all of the measurements because the scale tares to -5g, but due to some unresolved wobble it is 2 off by the time its finished

The measurements itself I take with a +- 5 grams expected deviation under 1000 grams

At 3000g it is 30g off and at 2000g it is 20g off

I don’t mind this too much because if my rockets produce 3 kilograms of thrust, I could care less about 30g

This will require further calibration and tuning of the assembly to reduce

And as you can see, the maximum thrust produced is 35-40 grams, which is less than ideal for a 30 gram rocket, but still measurable using the STTS

With these measurements total thrust and other things like expected apogee and payload capacity can be calculated, which is the intent of this device

As always more work is required but I have proven that it works and learned more about my rockets and what to improve in the process

(Side note, if anyone wants the raw data, code, or other information / resources, feel free to contact me)

4 thoughts on “Static Thrust Test Stand (STTS)”