I’m making a note here: HUGE SUCCESS.

GLaDOS, Portal

Almost 2 years ago, I stepped out into a field, attempting to test this brand new motor I received, and utterly failed.

Today, I succeeded not only in testing this motor, but successfully firing it as well!

The technical intricacies of how I came to be at this point, as well as some plausible excuses for my procrastination, are coming at a later date.

There is 2 years worth of material and background to go trough, and just getting all the pictures together in one place is going to be a task in and of itself.

So, to not delay things further, I will be uploading the test results first.

Preparation

When we1I don’t do this alone, I get a lot of help from an associate of mine who made this possible in the first place arrived at the test field, it was being closely guarded by horses.

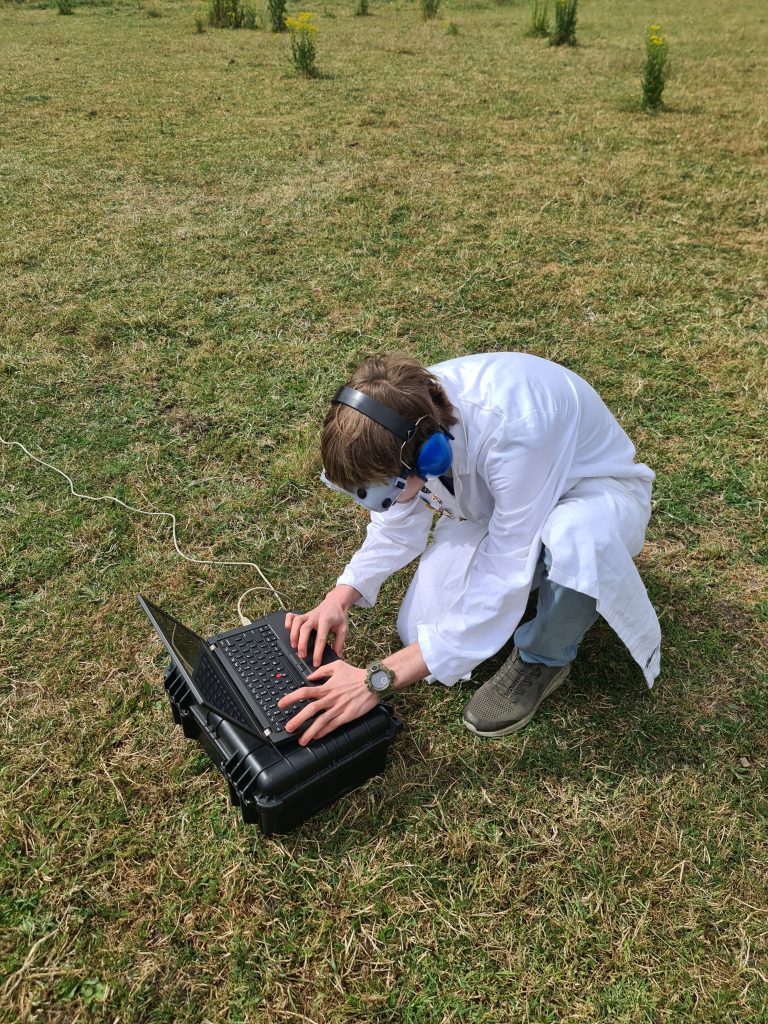

After passing them at a respectful distance, we commenced in unpacking and installation.

I do not have many pictures of this process because we were mainly busy with getting it done.

It was at this point that another two horses came closer to get a better look2One of them, at least. Not sure Daredevil over there could see us

To be fair to them, we were on their turf.

With some difficulty, we managed to shoo them away, for their own safety.

Hope for the best, Prepare for the worst

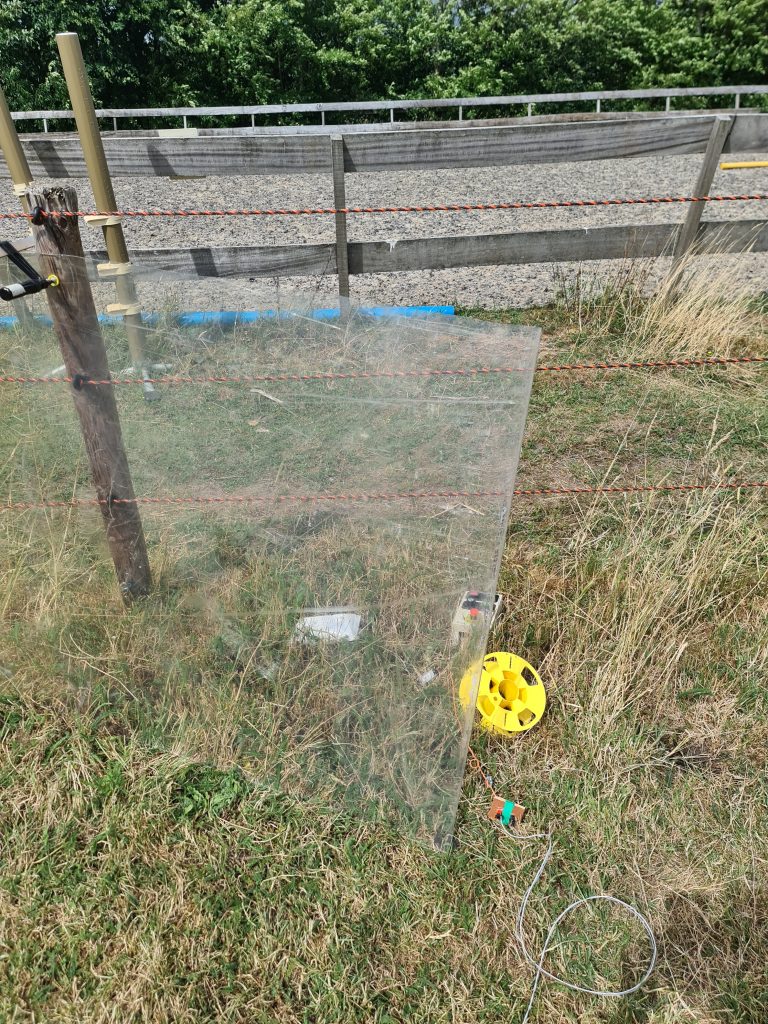

So, I hoped for the results we got, but I prepared for a big, badly timed explosion.

Fire Retardant3Water, Medkit, Plexiglass shielding4I call it my “Mythbusters Shield”, a safe distance.

You name it.

Rocketry is only fun if done safely, in my opinion.

Anyway, after this the horses left us alone, so we continued preparing everything.

Turns out I had not installed the software I use for logging the test results onto the laptop I brought, so I quickly installed and configured that (Luckily I had reception out in the field)

After everything else was done, the data was flowing, and the camera’s were rolling, I squeamishly inserted the igniter.

After this, I armed the system, and we quickly retreated to our little hideout.

But that is enough preamble, now it is time for

The good bit

What a result!

It seems to have gone perfectly, although anything this big is rather new to me.5Calm it

And more importantly, nothing blew up!

As for the data, it is still being worked on, and will be added here when analysis is finished (I’m having some trouble with Impulse Calculator 2000)

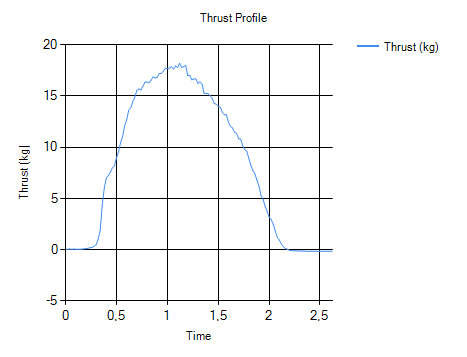

For now, I do have a graph and some rough numbers.

This hit a peak thrust of 18 kilograms!!6Well, it might have, the recorded value is 18.004 kilograms, and the scale is accurate to only about 5 grams, if that, especially given that this is the first time this much pressure was put upon it during a test. 7I’m still calling it 18 kilograms though.

Total Impulse is somewhere the 214 Ns mark

For reference, the previous record (as set by R-13) achieved “only” 8.07 Ns8Which also means this motor is around 26.75 as powerful as anything before it

More data will be tabulated when I finish refactoring Impulse Calculator 2000 sometime this week9Hopefully

And, with this test out of the way, I can start designing a rocket to put this motor in, and simulate how high it will go.

My design goal is 1 Kilometer with a successful recovery, and I have 80 days to get it done10I plan to launch during the upcoming national launch day organized by NERO, which falls on the 21’st of September this year

More about this when I know more about it.

Something else of note is the pervasive smell of burnt plastic emanating from the motor after testing.

This can be explained by the 3d printed spacers (Made from PLA) that separated the fuel grains for proper ignition.

And also, to a certain extent, the paint and possible plastics on the cardboard packaging material used as a liner.

But this seems to not have been a major problem, so in the name of consistency these factors are going to be kept.

Here are some post test pictures:

A special thanks to M and co for allowing us to use their field in the name of science

Thank you R for doing half the work

And thank you to L for sending this motor, and for the assistance in getting it to work12Names are truncated in the name of De Algemene Verordening Gegevensbescherming 13Welcome to Europe!

Stay tuned for updates on the big launch!

(Perhaps even subscribe to my newsletter)

top!