Overview

After being gifted such a beast of a engine it was quickly deduced that a different Static Test Stand had to be devised and built for proper testing

It took allot of time, resources and outside help, but its finally finished

So I hereby proudly present: The Static Test Stand – eXtra Large!

Full cellulose construction with ferric parts (Wood and steel), a 100Kg load cell + Amplifier, and more!

Here is a comparison of the new STS-XL versus the old STTS system

| Stats | STTS | STS-XL |

| Size (Cm) | 15x15x8 | 80x30x41 |

| Max Thrust (Kg) | 5 | 100 |

| Max Read Speed (Hz) | 80 | 80 |

| Default Read Speed (Hz) | 50 | 50 |

| Max engine diameter (mm) | ~30 | 38 |

| Max engine length (cm) | 13+ | 30+ |

Now this test stand was developed for a different purpose than the first one.

Namely, it has been specifically engineered to characterize MM-38, while the old STTS system was made to test various small PVC engines

This can be seen quite clearly in the below picture

The idea, for those who don’t know, is that by measuring the thrust a engine produces (using a scale of sorts), the total impulse, or power, of the engine can be concluded

This is essential for calculations, determining efficiency and comparing against other data

So this entire thing is basically a glorified kitchen scale for rockets, when it comes down to it

While it has yet to be actually used as of yet, the construction has been finished, and is final as far as I’m concerned

Speaking of construction:

Construction

It took many hours, multiple trips to the hardware store, and allot of help from friends and tutors, but I can safely say that this is the most solidly constructed thing I’ve ever had a part in

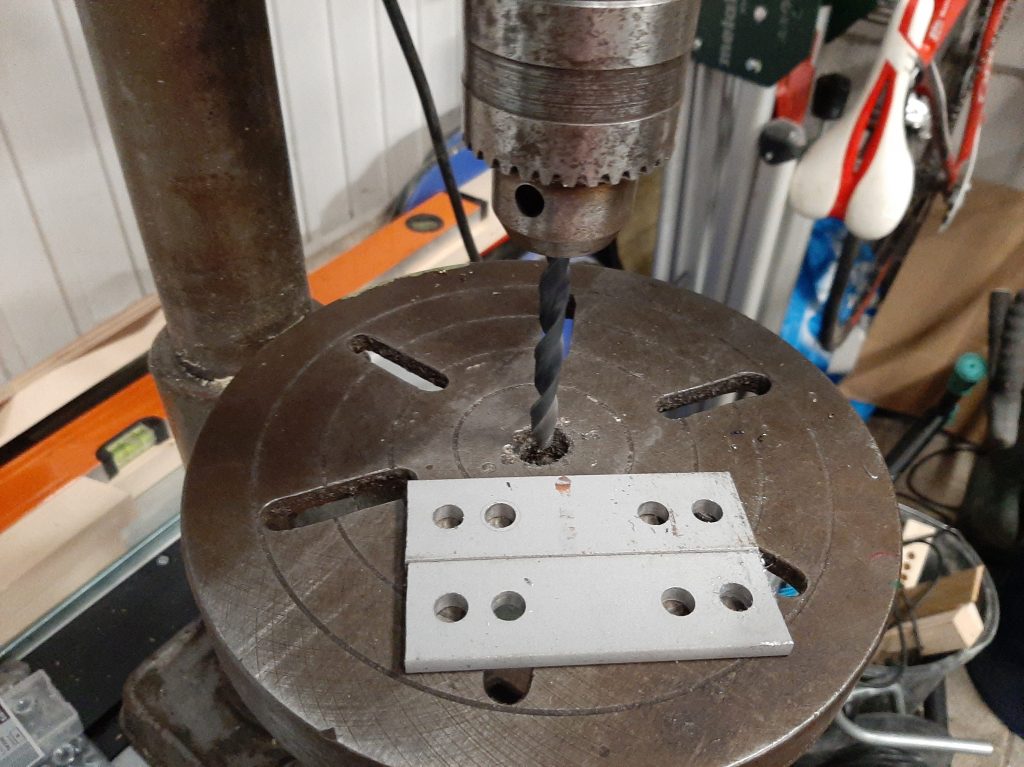

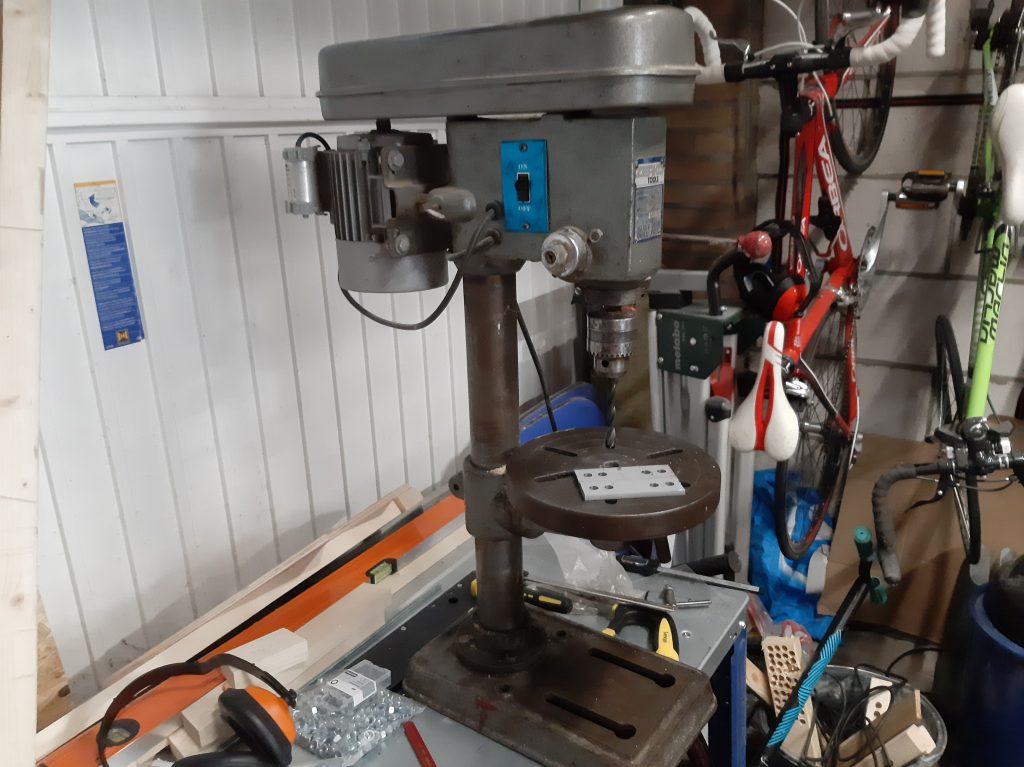

A very good friend of mine happens to have a well stocked workspace and a few hours on hand, and most of the final construction happened there

(The old versions have been left out for the sake of brevity)

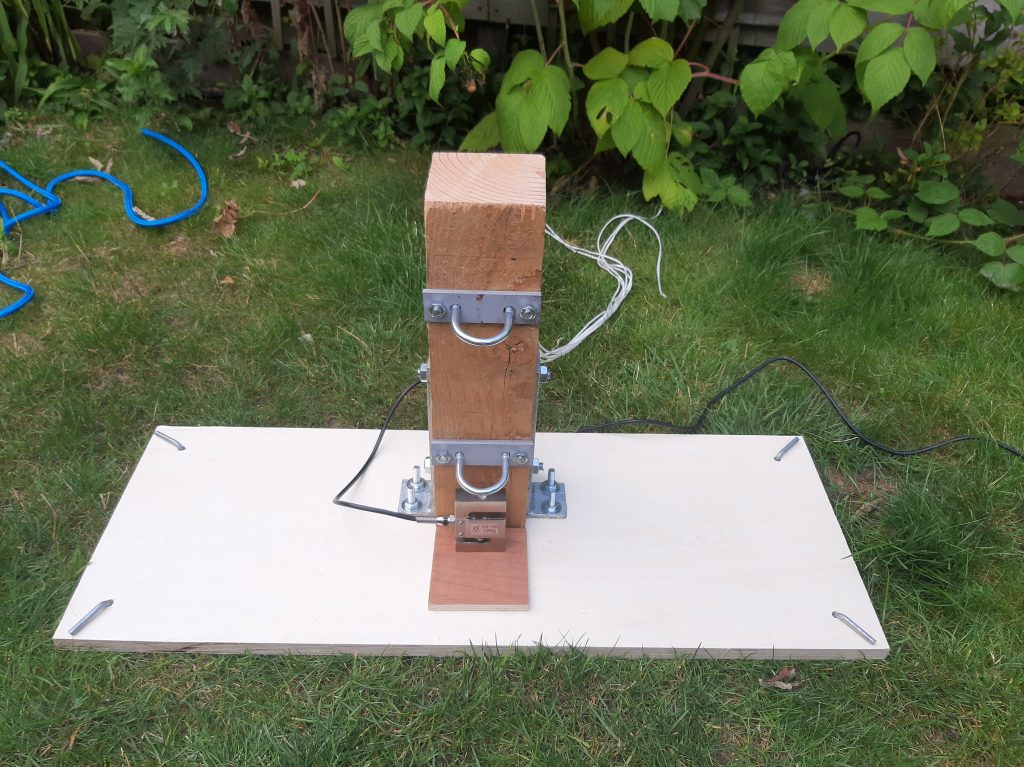

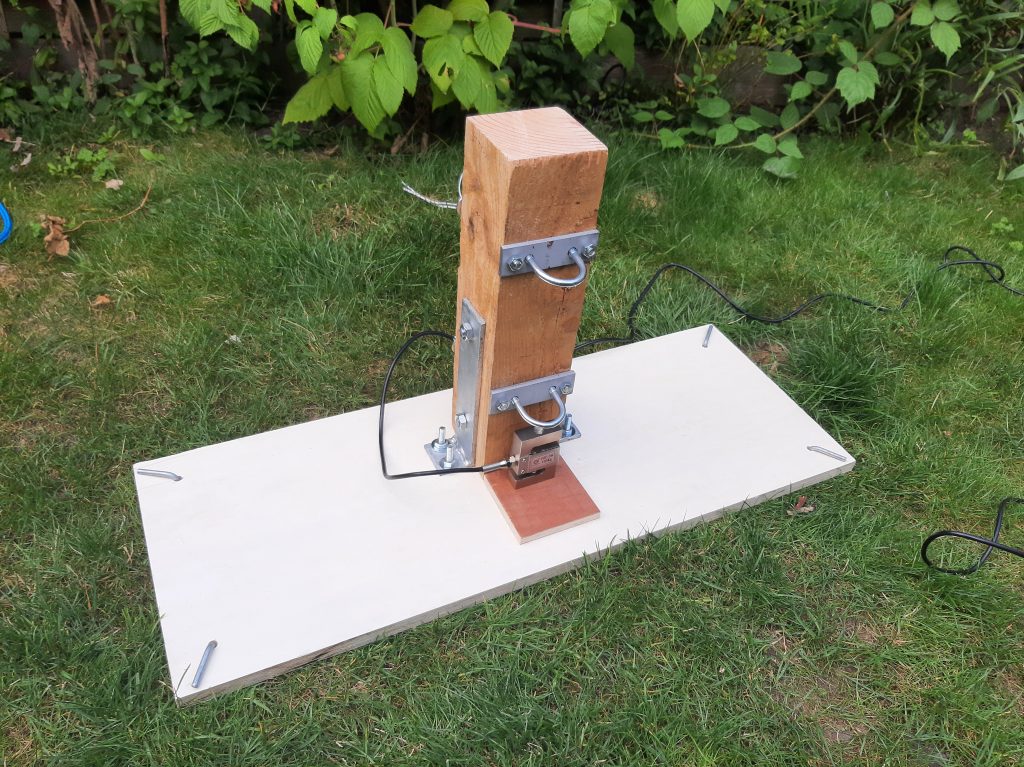

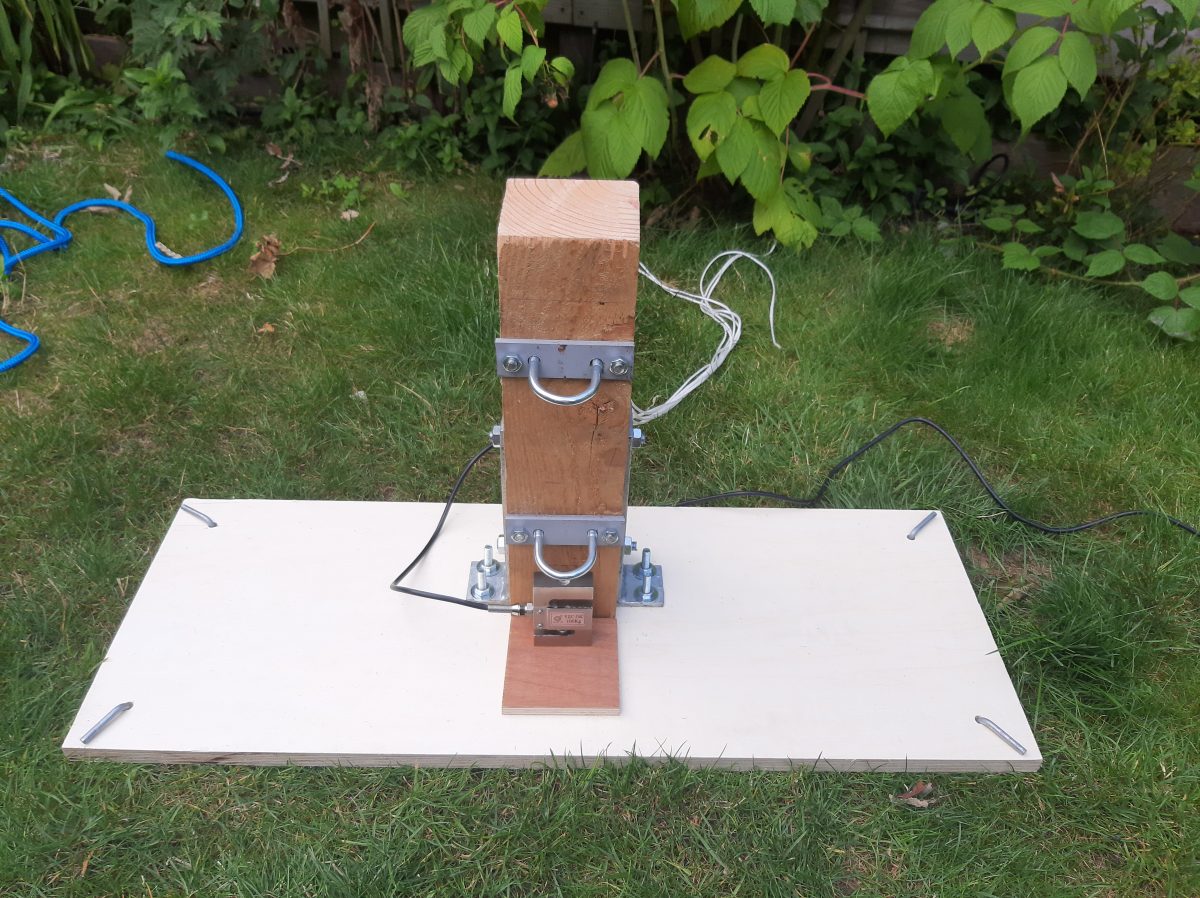

Its made of a main platform (or plank if you must) to keep the whole thing stable during testing

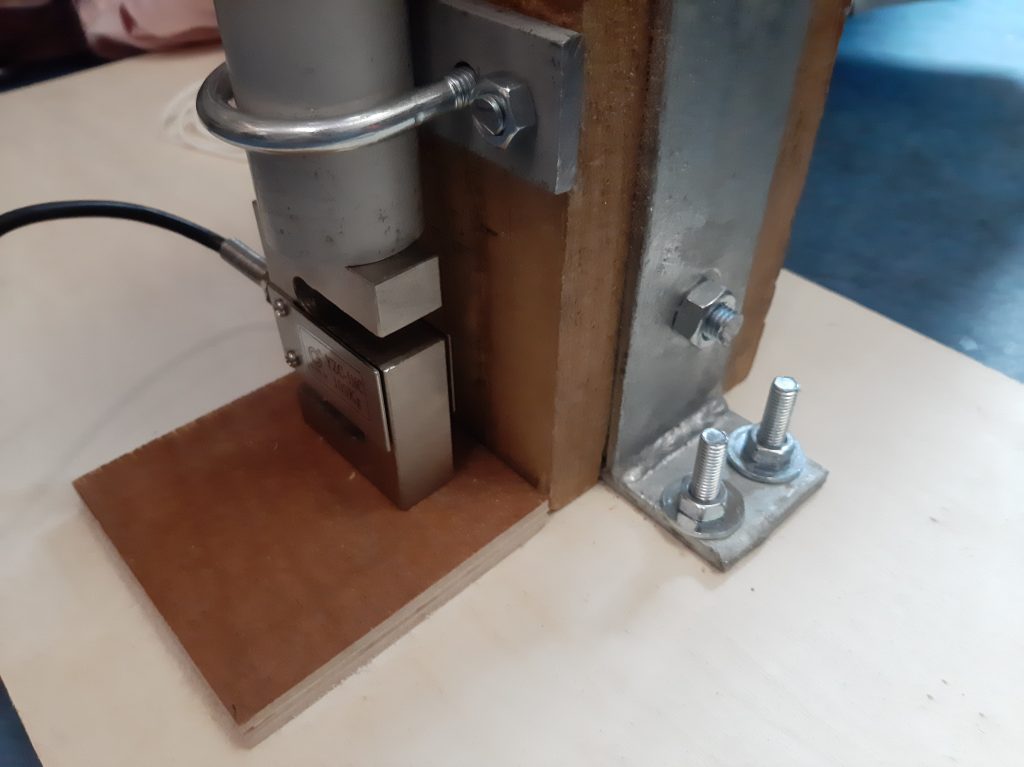

A 100mm x 100mm cellulose beam is used to hold the engine in a stable and upright position, so it can transfer its RAW POWER directly onto the 100kg load cell

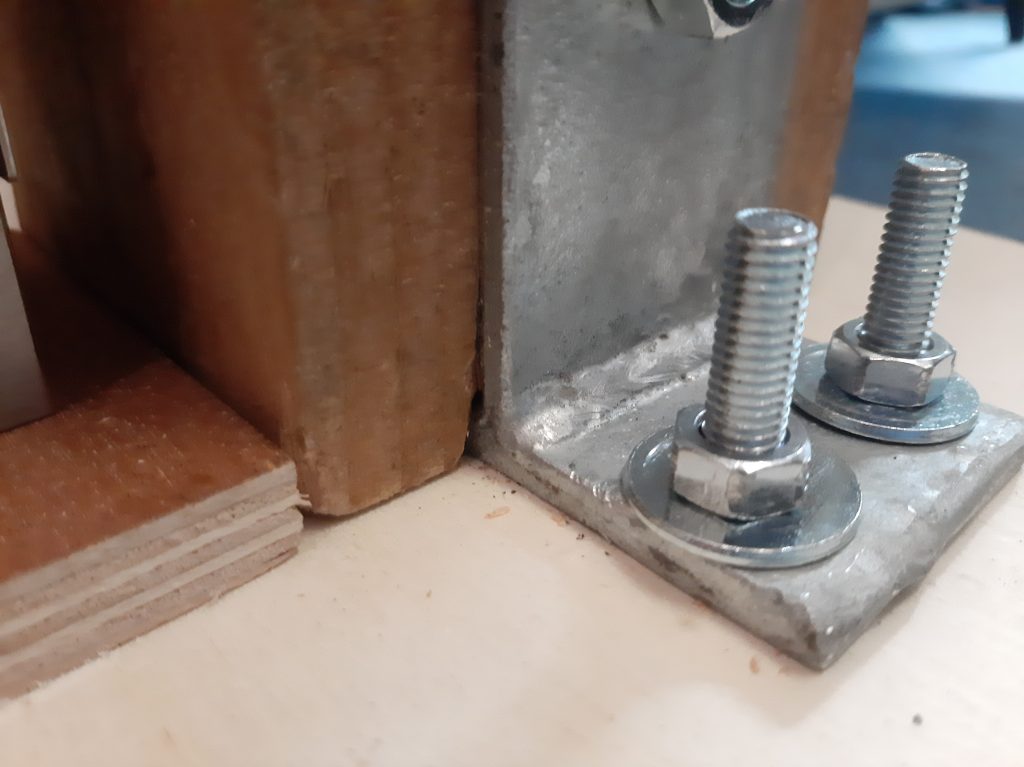

The beam is securely attached to the base by a pole holder, which has been cut in twain to make it fit the slightly-too-large beam, and is bolted to the base with 4 large bolts

2 large bolts have also been driven trough the entire beam, and hold it together securely to the holder and thus the base

A groove has also been cut out of said beam, to allow the holder to sit flushly into it

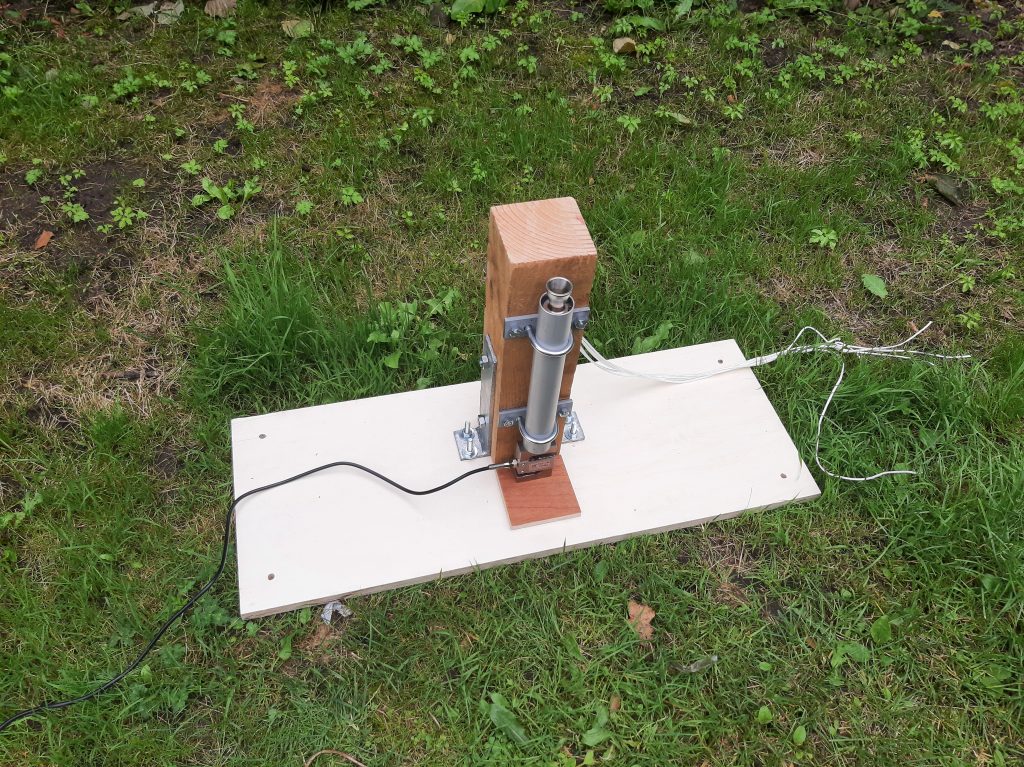

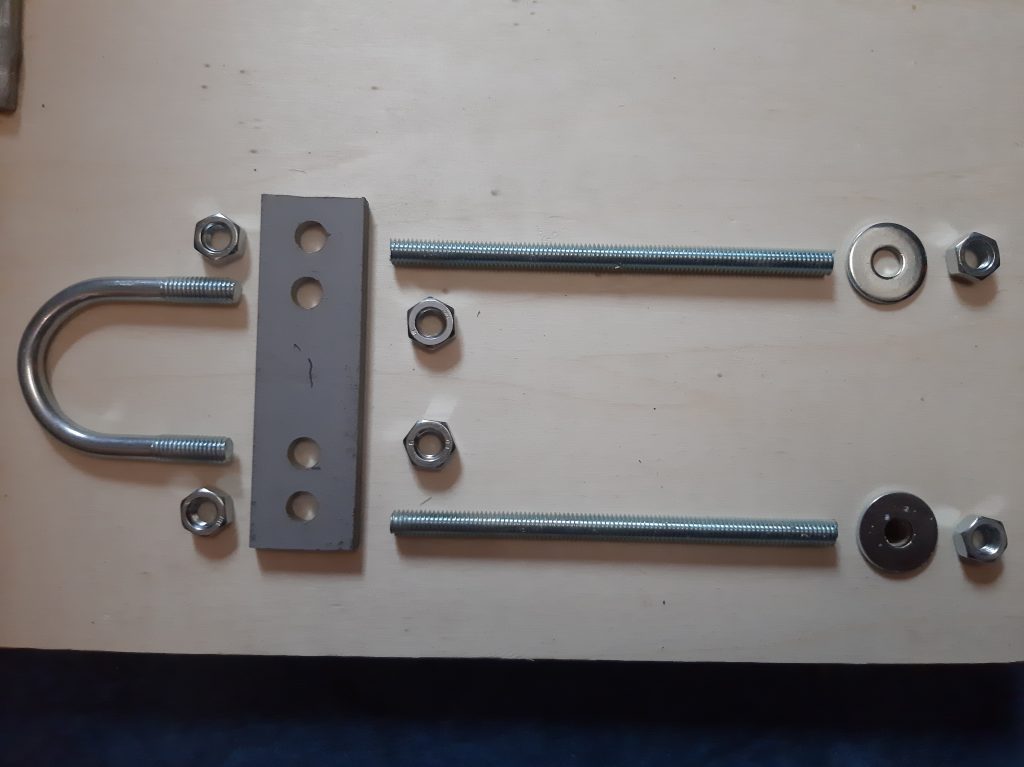

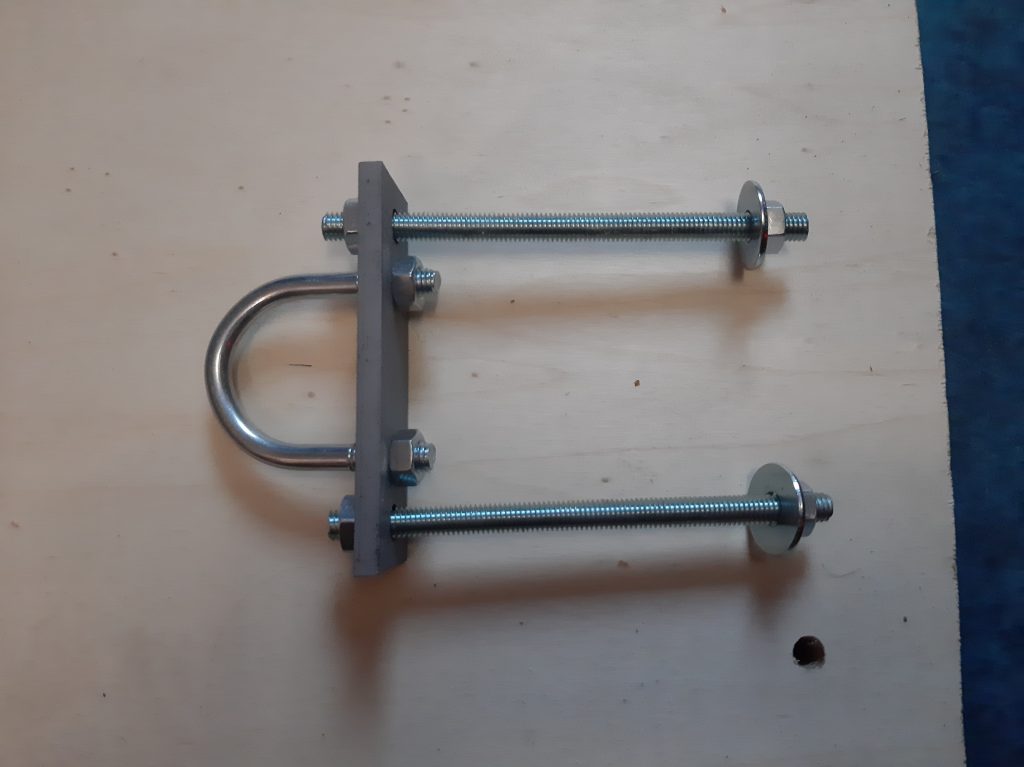

The actual holding is done by 2 steel plates, with 38mm “exhaust clamp’s” threaded trough

There are two of these to make sure the engine does not wobble about at all, and this seems to work well

Base stability is also not something to overlook, and it has been constructed so that it sits flush with the ground, and can be further anchored with 4 pegs using the attached peg holes

The entire point of all this construction is that the engine pushes in one direction, straight down onto the load cell

If it pushes in any other direction this can be considered a catastrophic failure of the test stand, and also remarkably dangerous

The worst case scenario would be it toppling over, resulting in a unintended rocket sled that could wreck havoc to nearby grass, let alone the program as a whole (and would result in a severe lack of readings, while giving too many results)

If safe distance is maintained, the only scenario in which people could conceivably be severely hurt would be a total disconnect of the attached motor during firing, which could hit someone at any range at which it could be seen

I am most sure both these scenarios have been preventively prevented to the best of my ability with thoughtful construction and planning (assuming people keep a safe distance)

As a final safety measure to make more than sure that under absolutely no circumstances it can ever topple over, there is a attachment that allows up to 6 further pegs to be attached by guy lines, pictured here

And last, but not least, possibly the single most important part

The plate to which the load cell attaches

Due to wanting to keep the underside flush, the load cell has been attached to a different plank than the base, because insetting the but into it would have severely compromised the structural integrity

So instead a smaller and stronger plank has been glued on top of it, with a hole trough the bottom of the base to allow access to the nut

Since this plate supports and furthermore spreads all of the thrust generated by the engine, great care has been taken to ensure adequate sturdiness, which i deem to have worked

Oh, and I almost forgot about the electronics!

While the actual construction merely serves as a safety measure, the thing it constructed of course has the purpose of measuring thrust

This is done trough a load cell, which is a block of steel with resistors on it that get more resistive the harder you push on the block

Its ever so slightly more complicated than that, but this article is long enough as it is

Its basically a digital scale, in fact its what digital scales are built out of

But it needs some processing, which is done in the plastic box

Inside of the plastic box (which exists mainly to keep dastardly moisture out) is, quite simple, a Standard Issue Arduino Uno and a HX711 amplifier

Or, a tiny computer and a way to measure weight

All the computer has to do is convert what its reading to a sensible unit like kilograms, and send it over to the computer, which just logs it to a file

All of these measurements can then be thrown into Impulse Calculator 2000 to get the (specific) impulse, and from there on calculate fun stuff like maximum height and thousands of a space shuttle

Also, if anyone is interested in the code of this, leave a comment or write me a email, and I’ll upload it to github

Anyway:

All external connections have been waterproofed with hot glue, and between the long cable the Chinese generously attached to the load cell and the many meters of USB cable I provided, more than enough distance can be kept between it and the engine

This box is not the greatest thing that I have ever constructed (that would be the STS-XL itself), it gets the job done, which is all that its there for anyway

The main trouble with all this now is that it needs to be calibrated

Something I’m not good at

I need to get a different scale, and make some test weights, and work it out from there I think

But it is of note because before proper calibration no tests can actually be conducted

Conclusions

No plan survives first contact with the enemy

Helmuth von Moltke the Elder, paraphrased

While not a machine of warfare, I think this quote is quite pertinent to STS-XL

Because while I have planned for its use or partial failure, and have built it according to that planning, I have yet to actually use it

And until I actually use it I wont know for sure it works

Another quote that I quite like is

The difference between theory and practice is often greater in practice than in theory

What I’m saying is, is that while I did everything in my power to make it as safe and sound as possible, and have planned for any catastrophic contingency I could think of, I wont know for sure how it will behave until I press “GO” and the engine lights

At which point, if its going to fail, its too late to do anything about it

I guess we will know soon enough, as the test is planned for the coming few months, this year at least if nothing severe gets in the way

I have also just realized, that if the test were to be successful, further testing of this engine would not be required (assuming the data gathered is proper)

This is of note because this thing has been engineered entirely for use with this particular engine, and would require allot of work to convert to a different one

Its not particularly hard, but I could have been better off designing it in a more forward thinking manner

But what’s done has been done, and STS-XL sure is done

When the test of MM-38 has been completed, the results will of course be posted up on this site, and a link will be placed here

Thank you for reading

Hi Denneth,

That is looking quite solid. Keep up the nice work.

Regards,

Leo

Nero rockets