Hopefully, the 27th time’s the charm!

Grant Imahara, Mythbusters

I made the casing 20 design in begin December 2020, and made a total of 4 (R-6 to R-9) in the following 3 months.

R-6 had a structural failure at the nozzle, ejecting it right after firing

R-7 Had had a structural failure slightly below the nozzle after 1 second, leaking pressure and thus compromising performance

R-8 Used a cast gypsum nozzle, which eroded away nearly instantly, resulting in loss of performance

R-9 Had too big of a nozzle (and possibly bad fuel) resulting in a lack of pressure and thus lack of thrust

After R-9 the program kind of stagnated, with time being spent on various other projects (ICBM-Micro, PEST, RFC-1.2, Parachutes, Impulse calculator 2000, ICBM-V2, and MM-38 fuel casting and testing equipment development, just to name a few)

And now, 5 months after R-9, I decided on a whim to make R-10

I had a good idea of what went wrong with R-9: Low chamber pressure due to too large of a nozzle diameter, this was due to using a slightly larger washer than usual

I also thought of a solution to this: putting the smaller washer underneath the larger one to provide good sealing but also a smaller exit diameter

And seeing as I was so close to getting them working before moving onto other projects, and having a lot of spare time and materials, I decided to test it out.

R-10 is the first one which had no structural failure, nor a excessive burn time

It was created and tested within a day, without assistance, which is a new personal record for cast fuel rockets.

And while it did not give spectacular performance, and could have burned a bit shorter, it did work, without miscellaneous structural failure.

This is also the first time ICBM-V2 has been used to ignite a actual rocket

It performed exactly as advertised.

Construction

The fuel (as usual) is KNSB (65/35), the main difference being that it was half leftovers from previous castings due to a temporary fuel shortage together with laziness

This was then molten on a new induction heater, the idea being better temperature control

This was not the case, but it worked eventually

Due to the low amount of fuel and losses due to a less than optimal setup, not enough fuel could be melted to fill the whole 8 centimeters of the fuel compartment

Since no extra fuel was available, I instead worked around the problem;

with a hacksaw

After sawing off 1 centimeter of empty casing, I glued on the nozzle

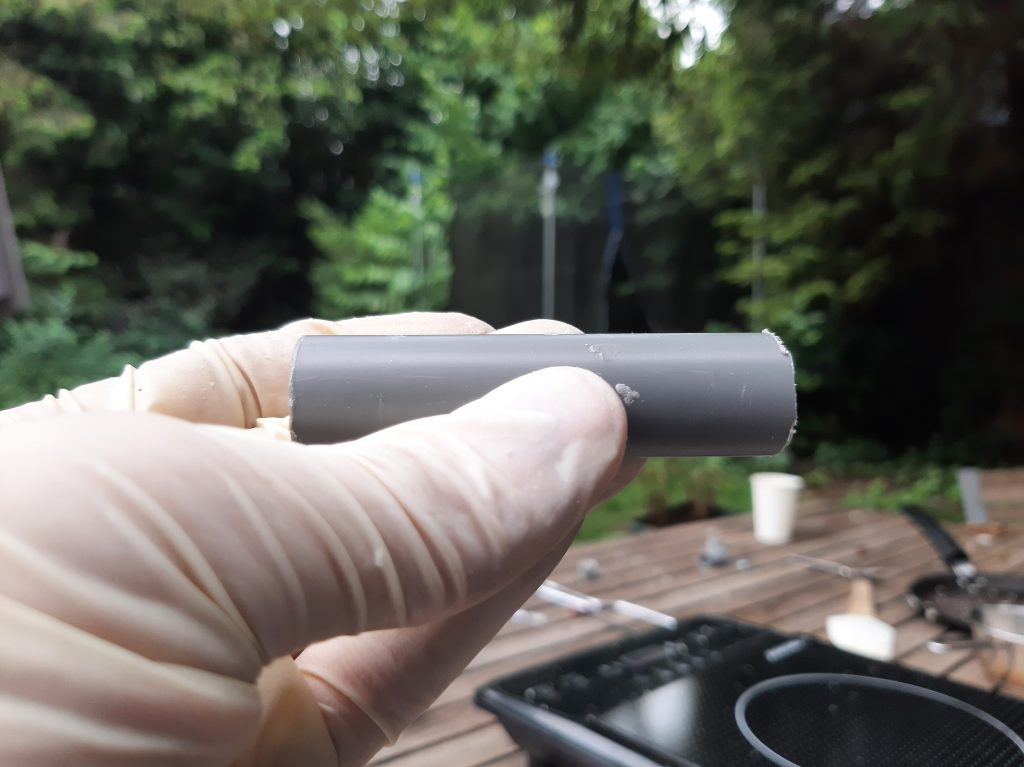

The nozzle this time around consisted off 1 smaller and 2 large washers, the small one being sandwiched between the 2 providing the smaller diameter, with the large ones fitting snugly to negate leakage

This was then left to dry while I prepared the ICBM and STTS for testing

I also, to mix things up, decided to film the fueling process

Here is the compiled time-lapse:

And here is the finished product:

Note the second washer having a smaller exit

Testing

And now for the test itself:

In the second video you can see the thrust being directed to the right partway trough, before returning shortly thereafter

I can offer 2 potential explanations

– Temporary clog on one side

– Internal nozzle ring shifting during firing

I could imagine the effect this would have during flight could be catastrophic, so it is of note.

R-10 after

Results

| Pre Test Weight | 39.33 g |

| Post Test Weight | 26.14 g |

| Difference (average is 15g) | 13.19 g |

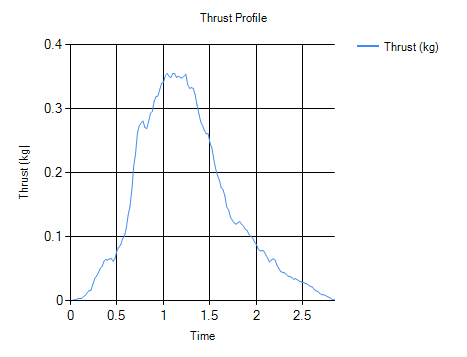

| Total Impulse | 3.8932 Ns |

| Average Thrust | 1.3612 N |

| Peak Thrust | 0.355 Kg |

| Thrust time | 2.86 S |

| Motor class | B |

| Specific Impulse (Ns/kg) | 295.166 |

| Specific Impulse (Sec) | 30 |

The thrust is nothing to write home about, the whole fuel situation could have been a lot better, the impulse is less than most previous tests, the burn time could have been less, and its less than 10% efficient.

But even though all that is true, it still worked, and nothing failed.

That last bit is important, this one functioned without any structural failure and without a unusable burn time.

so I’m counting this one a success, 8 months after conceiving of this engine Ive made the first one that worked fine.

Further improvement is still needed, and might never come due to focus shifting to higher power metal motors

As always, the raw data (In a 7-Zip archive):

I also recommend Notepad++ for viewing and editing

Further Testing may yet still happen, but right now much of my time is going towards mm-38 and its assorted sub-projects

Who knows

One thought on “R-10 Test Results”