What goes up must come down

Gravity

Making something go down is quite easy, you just let it go from some height and it will swiftly hit the ground

Making something go down slowly however is quite a challenge

To make sure my future rockets can be recovered in 1 piece without Lithobraking I have started working on parachutes

The first thing I did was make a very small, crude parachute, mostly to see what would happen

While there was a attempt, no real measurement or structure was used to create it

I’ll be the first to admit that this was far from a controlled environment, but that was not the point, since I mostly wanted something to do

The construction was quite simple, 4 elongated trapezoids, taped together with 8 strings attached

To this string a small log I found in the forest was mounted to provide a weight for throwing and deployment

But, it did work, and could survive the speed of a slow car

Notice how at certain points the parachute collapses in on itself, this is because when a “flap” folds over more air hits it, causing it to fold over more making it worse

The main problem other than poor material choice (Knitting String and a old duvet cover) was the rather small surface area

Since while it did slow things down, it didn’t do it to a useful degree

There is of course a easy solution to this problem

Build a bigger one

And so I did

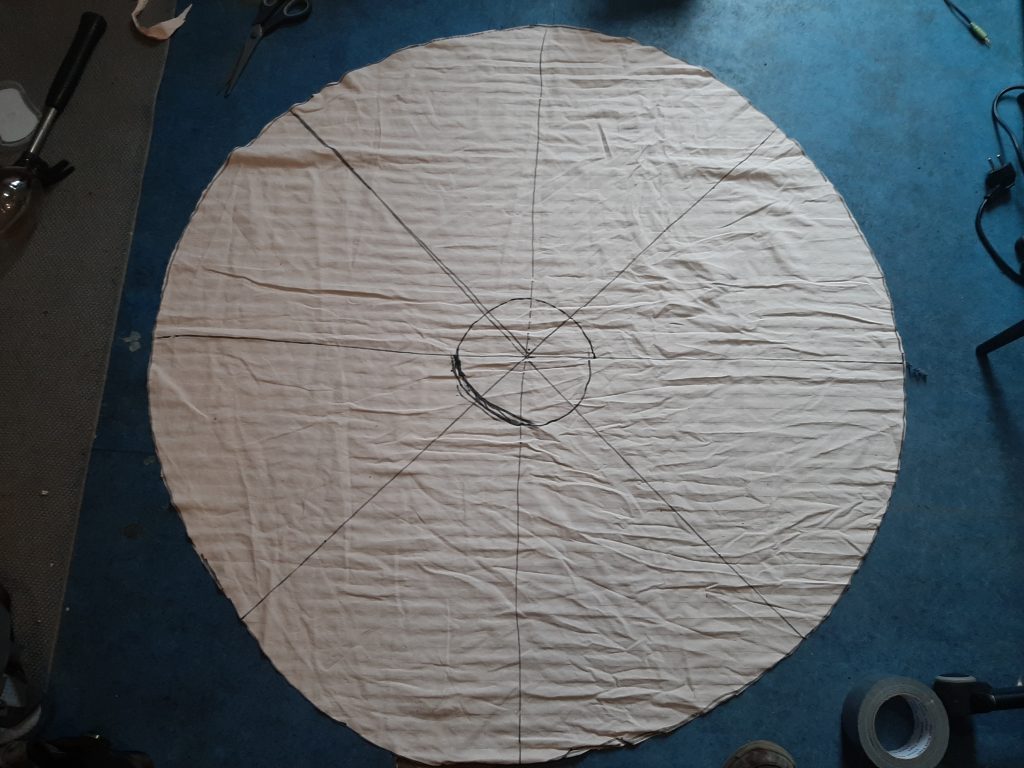

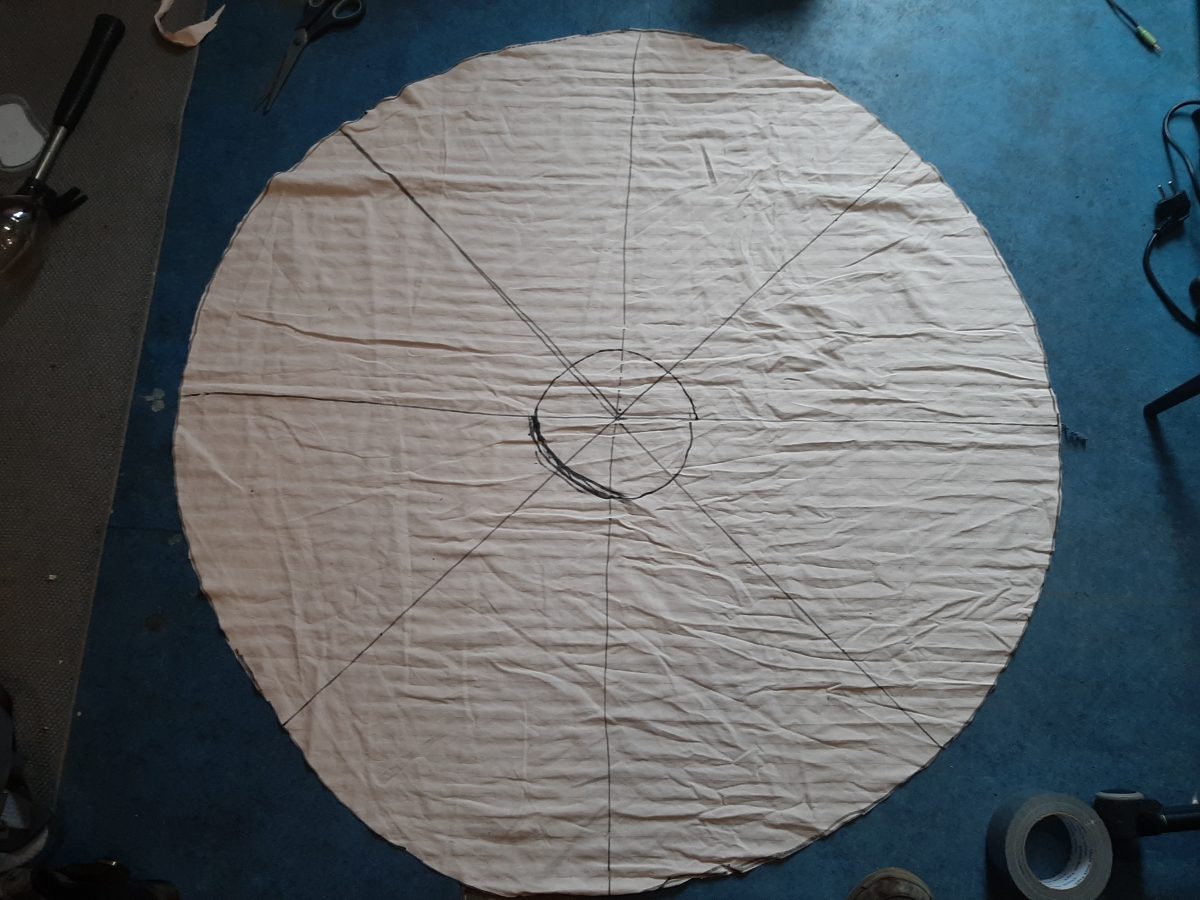

I started out by taking a square-ish™ piece of duvet cover fabric and taping it to the floor to simplify the drawing process

After which a circle with a rough radius of 55 cm was drawn using a improvised circle plotter

Then, the center was found and marked and 2 lines were drawn trough it

The center point between those lines was found and more lines were drawn

Then, a rather crude circle was drawn with a approximate radius of 10 cm

Excess cloth was then removed together with the middle circle

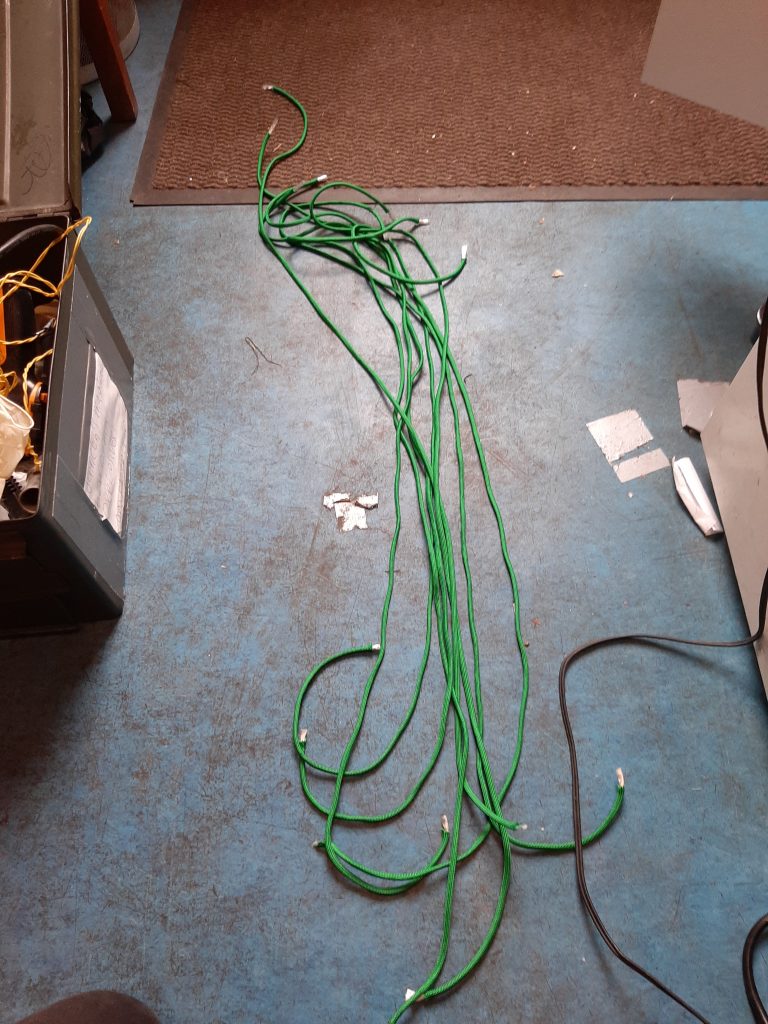

8 pieces of 550 Paracord were cut to 1 meter to act as tethers

These were attached to the chute by first reinforcing the attachment point with duct tape, then punching a hole trough with a office perforator and tying them trough

They were tied together at the bottom to form a attachment point, and to this point a 0.5 liter soda bottle filled with water was attached

This is to serve as a test weight

Soda bottles were chosen for this due to availability, utility and standardization

They are standardized, making control tests a lot easier

And half a liter of water is roughly half a kilogram, making them perfectly suitable for weighing things down

The main reason for having a test weight is that it was found quite early on that in order for the parachute to deploy, more force needs to be applied to the strings pulling it down than the parachute enacts upon itself

In simpler terms, if the thing under it is not heavier than the parachute itself, it wont deploy but rather invert or flip

This whole debacle took about 1 hour 30 to finish, after which testing was conducted by repeatedly throwing it of my balcony

As you can observe it works pretty well

After throwing it about a bunch I decided a more scientific approach was required:

Since they both landed in about the same place and I know the frame rate, I can measure how long it takes them to hit the ground from when they first enter the frame

| Data: | Frames | Seconds |

| Bottle (Control) | 14 | 0.466 |

| Bottle with parachute | 35 | 1.166 |

As you can tell, it slows it down a significant amount

A difference of 85.71% to be exact, or a 150% increase

I also counted the frames from the top of the swing-set, since i noticed it took the parachute a short second to properly deploy

| Data, Swing-Set Edition: | Frames | Seconds |

| Bottle (Control) | 6 | 0.2 |

| Bottle with parachute | 14 | 0.466 |

Absolute speed could however not be determined, since there is no good reference for distance traveled

A better testing method will have to be devised to provide consistency and more data (multiple options are being considered, including rooftop deployment stations and catapults)

(27-07-2021)

I made some more videos right after this was uploaded, and forgot to upload them

So here they are

So, now that I have proven the design, it is time to build it from proper material

The cotton fabric used for these tests is quite thick and heavy, making it harder to deploy, less effective, and requires a bigger fuselage for deployment due to the volume

My 2 options for replacement materials are synthetic tablecloth or “Mylar space blanket“

Plastic tablecloth has the advantage of being cheap, thin, light, easy to work with, relatively sturdy and readily available

This is considered the safe choice (for my budget)

Mylar however has the advantage of being incredibly light and unbelievably thin (~14 µm)

It is also quite difficult to work with, being very prone to tearing

Depending on how testing goes, Mylar will probably be chosen due to how small and light it is making stowage trivial, I do foresee it being hard to mount ropes to, since my ordinary paracord might weigh it down too much, and I am unsure of the tensile strength and if it will survive deployment

Only time will tell

This will be tested quite soon, and when this has been completed the data will be published as a second part (Which will be linked here), since I did not want to await phase 2 testing before doing a write up

(Note: Due to motor development parachute development has been put on indefinite halt, it will continue after the engine work has finished)

One thought on “Prototype Parachute Development (1/2)”