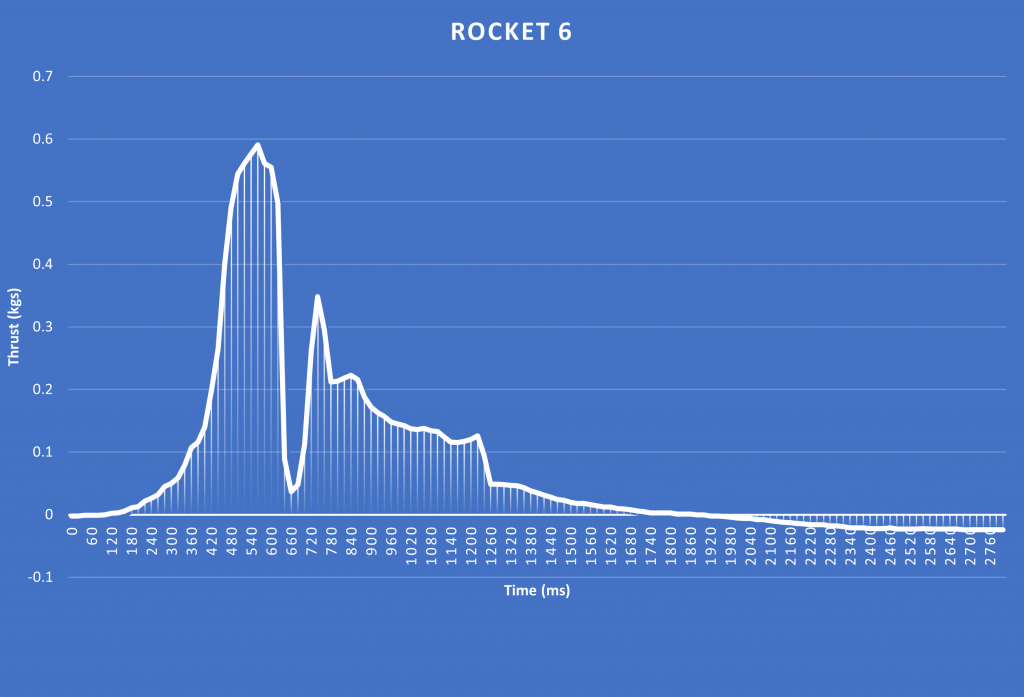

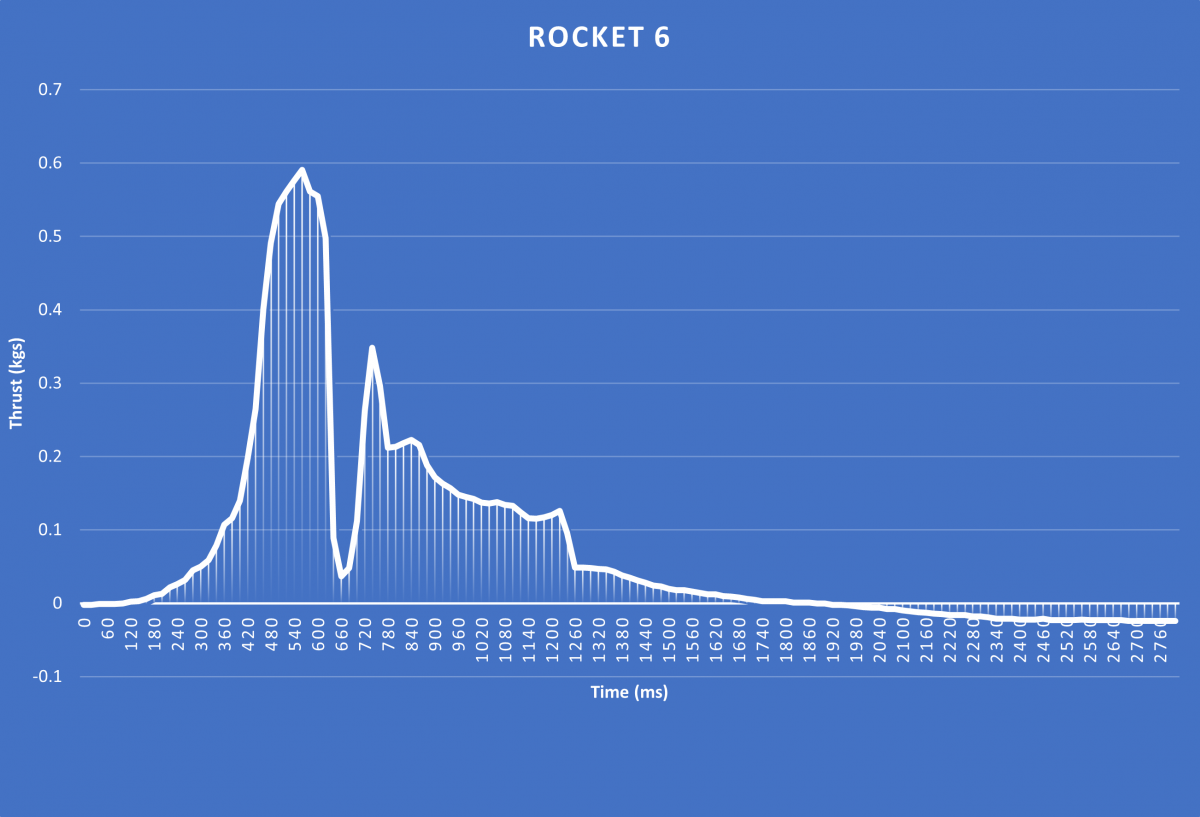

After acquiring new materials I immediately made a test rocket using my proposed Casing 2.0 design, here are the resulting results

(Due to a interesting casing failure I will also do a “frame by frame” analysis down below)

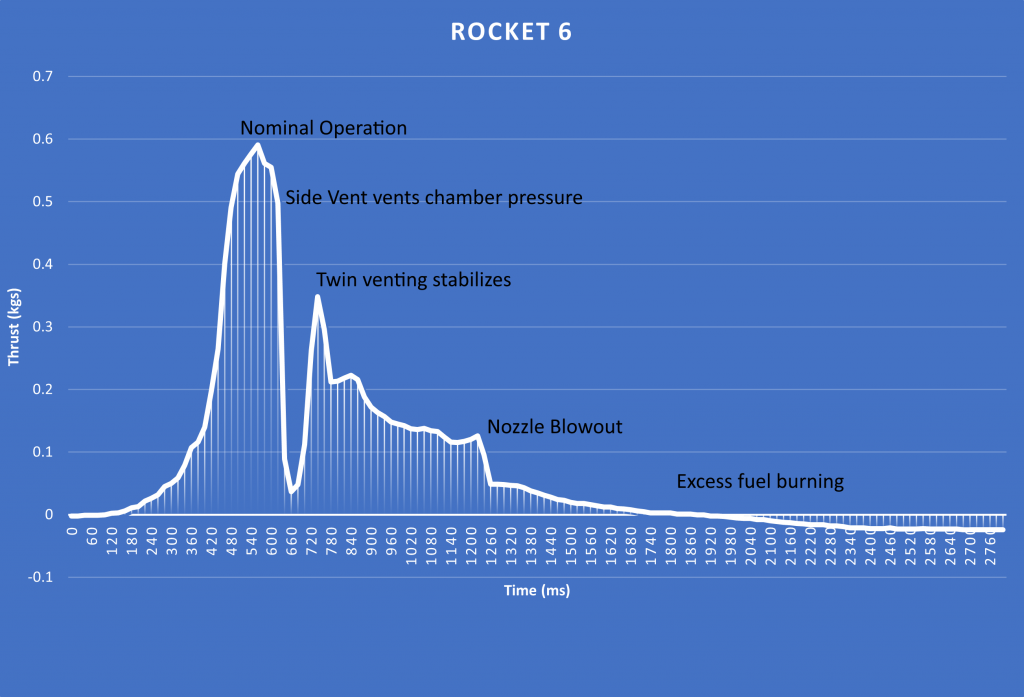

As seen in the video the nozzle blew out resulting in loss of thrust, but a few noteworthy things happened beforehand as well

My conclusion is that 2 side breaches of the main casing occurred, one on the inside of the nozzle ring and on on the outside, the latter being significantly smaller, resulting in loss of pressure, change in thrust dynamics, and eventual structural failure of the nozzle assembly and loss of thrust

The nozzle failure I conclude is in part caused by the washer diameter being only slightly more than the internal diameter of the inner tube, this allows it to free itself if enough force is applied or deformation of the nozzle ring

A solution offered for this is perfectly fitting nozzle washers, these are under construction and will be employed in rocket 7

It is also possible it was temporarily saved from this fate due to the glue holding the holding ring in place also holding it in place until thermal failure occurred

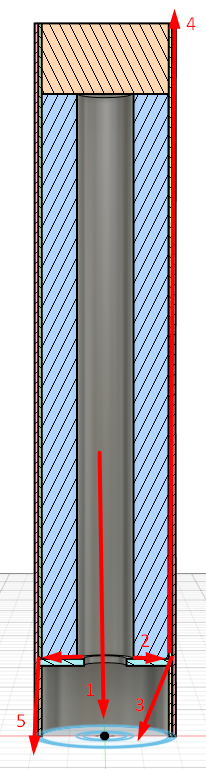

Here is a (Badly) drawn diagram of the (presumed / observed) pressure venting paths

1: Nominal thrust 2: Pressure escaping inner tube 3: Second (Inner) vent 4: Bottom vent (both sides) 5: Third (Outer) low power vent

Note the nozzle flying away after blowout and the pressure dip between nominal and double-venting

Now, Pictures:

I will try to fix this by applying more glue to reduce / stop bottom venting, and have a better fitting Nozzle to reduce or resolve blowout

If a better fitting nozzle fails, I will try more ring material and / or small nails holding it in place

Here is the raw data (In 7-Zip format again since WordPress blocks .log and .zip files)

I also recommend Notepad++ for viewing and editing

I’m also working on a MCCM (Mission Control Case Module, working title) including field kits for reloading igniters and spare parts etc, a (linux) laptop running a array of cameras and telemetry for more data, power and miscellaneous infrastructure and more

Ill be working on this in the background as a long-term project

Next up, Rocket 7!

2 thoughts on “Rocket 6 Static Test Results (Casing 2.0 first test)”