After the eventful launch of BTIR-1, it was realized a new vehicle needed to be designed.

And to facilitate this simulations had to be performed.

The idea for building R-12 was to get a proper thrust curve, so that total impulse and vehicle performance could be calculated properly.

R-13, which has also been built, would likely have a similar thrust curve since it was built according to the same specifications using the same material stock.

The idea being to simulate it using R-12 and to launch it using R-13.

This plan was foiled however, by combustion instability during R-12 testing. (more on that later)

It was still a important test however, being the first test using the STS-XL System.

The entire plan just described has -due to the disparaging test results- been moved down the queue, so to speak, with the plan now being to test R-13 using a Type II igniter, and move on from there.

And if you are wondering where R-11 is, that was the one made used in BTIR-1

Construction

Using the now standard Casing 2.0 design, with the things learned from R-3 to R-10 integrated, R-12 was constructed from 3 steel washers of 2 sizes, 2 sizes of PVC piping, 1 PVC adapter piece, and Bentonite clay.

The KNSB fuel was molten on a electric hot plate, left to cool until at a clay like consistency, and then molded into the piping.

(Not endorsed by IKEA)

The same was done for R-13, although I have little in the way of explanation for the disparity in grain core size (aka fuel hole diameter) comparing with R12.

(I’m actually very amused, trust me)

How rude!

With construction finishes, it was time for

Preperation

Now me and my fellow rocketeer often, but incorrectly, interchangeably use “Launch” and “Test”, leading to a lot of people asking how high it would go.

So lets make it clear, this (as are most my tests) is a static thrust measurement, in where a lot of noise, smoke and data is produces, but only micrometers of movement.

Better for data gathering and safety, more boring to film.

First, the equipment was hauled, even lugged to the test site (a nearby concrete footpath)

and Universal Serial Bus cable going to the Telemetry Platform (Other Left)

As always, check out pictures were taken, after which the rocket was weighed.

Some discussion later, it was decided to use the old Type I igniters, for consistency with previous tests.

This igniter was then promptly fabricated from 10cm of 1mm diameter

Ni-chrome Wire, some (now very) old sugar fusing, and plastic kitchen wrap.

The igniter was then inserted, and the measurement retaken.

And last, but not least, it was placed onto STS-XL.

The readings given by STS-XL matched those just measured by my precision scale, indication calibration remained correcting within a few %.

And now, for

The Testing

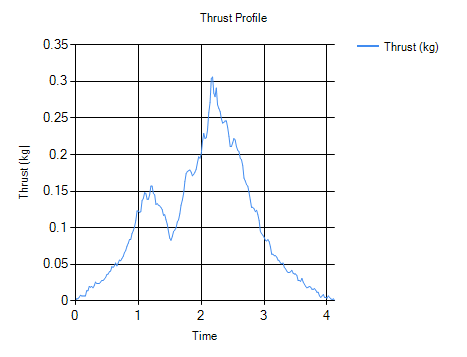

As you may have figured from the burn time, it could have gone a bit better.

And as you may have heard the thrust, when actually being generated, fluctuated wildly.

This is the foreshadowed combustion instability.

This becomes quickly evident looking at the thrust graph, as generated by Impulse Calculator 2500.

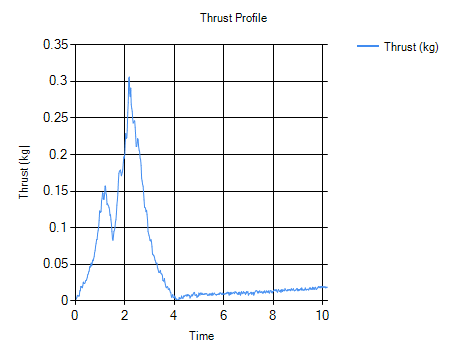

And here it is with “trail off”

This is, in fact, less than optimal.

In fact, these results were so troubling, that the aforementioned plan of using R-12 to simulate the trajectory of BTIR-2 was rejected, simply because these results indicated a rocket unfit for launching anything.

The actual results, tabulated below, are also less than encouraging.

| Pre Test Weight | 51.14 g |

| Post Test Weight | 31.44 g |

| Difference (average is 15g) | 19.7 g |

| Total Impulse | 4.128 Ns |

| Average Thrust | 0.992 N |

| Peak Thrust | 0.355 Kg |

| Thrust time | 4.16 S |

| Burn time | 12 S |

| Motor class | B |

| Specific Impulse (Ns/kg) | 206.430 |

| Specific Impulse (Sec) | 21.05 |

This is however even worse, efficiency wise.

While I won’t say it went wrong, it has definitely gone differently to what was expected.

The question now is, why.

More specifically, why these results, and how might I improve them.

My guess would be, the chamber pressure is too low.

This would explain the extended burn time and trail off .

This is most likely due to the nozzle diameter being ever so slightly too large.

Second would be the igniter.

The ignition using a Type II occurs only at the very top (bottom if oriented towards sky) of the combustion chamber, requiring more time to propagate down and ignite more of the fuel, also worsening performance.

And to address the elephant in the room, the thrust curve.

Or rather the thrust mountain.

My guess would be the nozzle being temporarily clogged with combustion byproducts, which increased the chamber pressure, which then dislodged the obstruction.

That would explain the combustion instability.

As for fixes:

- A new nozzle would need to be designed, possibly out of bar stock, with a smaller nozzle diameter to facilitate a higher chamber pressure.

- This brings the added problem that the PVC casings quite likely can not handle these pressures, incentivizing the switch to aluminum.

- A better igniter (such as Type II), to start up the engine more effectively and efficiently.

- Same problem as above, with the increased chamber pressure.

- A second problem would be that it would need to fit trough a even smaller nozzle, something the Type II (which was designed for MM-38) already has trouble with. possibly requiring a entirely new igniter type.

- As for the clogged nozzle, I have no solution for the clogged nozzle.

- I speculate it might prove to be less of a problem when the rocket is improved, since the higher chamber pressure might disallow build up in the first place.

All these fixes are to be applied to the rockets following R-13, for R-13 has already been built with the same problems.

The exception being the igniter, since it is planned to fire R-13 with a Type II.

This would provide further data on how the igniter choice impacts thrust and pressure, and would thus help design Casing 3.0 rockets.

When that test is done, it will be linked here.

As always, the raw data (In a 7-Zip archive):

I also recommend Notepad++ for viewing and editing

That will be all.