After the rather disappointing results of R-12, the plans were altered to test R-13 with a Type II igniter, to see if it would help with the pressure build up.

After a week off on vacation, work was resumed with me and my fellow rocketeer arriving at the test site.

Where it was almost immediately concluded that I, in my infinite wisdom, completely forgot the wire spool to connect ICBM-A and B together.

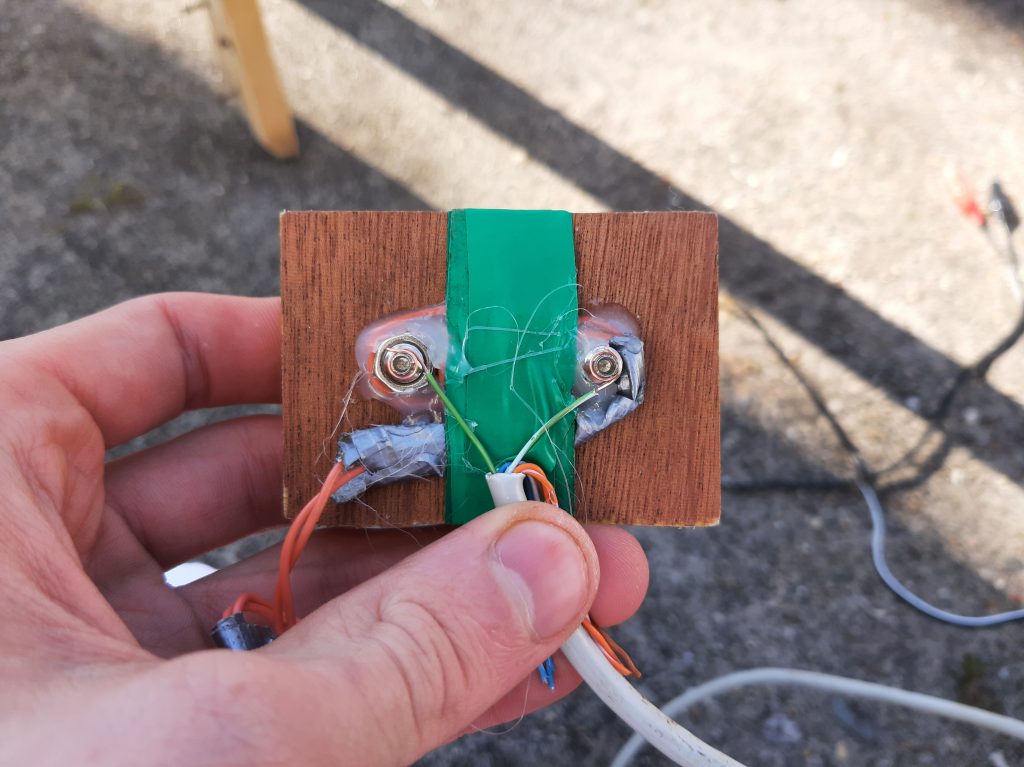

Luckily we could improvise something together and avoided having to blow the whole thing off.

My colleague found a disused Ethernet cable somewhere, and after sacrificing the connectors we had found our wire.

I quickly taped the green leads to the A side, improvising the B side together using the disassembled safety device, which was used to short together the inputs while in transit.

After that was done, delaying the test significantly, a igniter was loaded into R-13.

This too, went wrong.

The 4mm igniters would not fit, logically, trough the 3mm nozzle!

They were designed, of course, for MM-38, which is a order of magnitude bigger, and thus never suffered from this problem.

Quickly running out of both functional igniters, and time, I once again improvised.

I quickly, and on a whim, taped some leftover Visco Fuse onto the end of the igniter, and inserted the fuse into the motor instead of the entire assembly.

To my memory this fuse was about 1.5 to 2 centimeters long.

I sadly do not have a picture of this, nor do I have any pictures of the new data gathering setup, employing my newly acquired GPD Pocket 2.

This was due to the rushed nature of things. And sadly its mostly too late for that now, so I will instead show what data I did gather.

And luckily for me, there is quite a lot.

R-13 was of course weighed prior to firing, to provide reference into the amount of fuel spent, and then placed with the igniter assembly onto STS-XL.

And after the whole shebang was mounted, the STS was calibrated and the cameras were started, I pressed go.

And oh my, did it go.

Note how the smoke is propelled 3 to 5 meters into the sky

Note how the camera slightly moves due to the immense power just unleashed

As you can clearly tell, this one worked.

First off, the resulting data:

| Pre Test Weight | 51.80 g |

| Post Test Weight | 31.03 g |

| Difference (average is 15g) | 20.77 g |

| Total Impulse | 8.07 Ns |

| Average Thrust | 6.404 N |

| Peak Thrust | 1.047 Kg |

| Thrust time | 1.26 S |

| Burn time | 6.5 S |

| Motor class | C |

| Specific Impulse (Ns/kg) | 537.966 |

| Specific Impulse (Sec) | 54.85 |

If you have read about any of my previous rockets, you will see that this is quite the performance.

In fact, this is the most powerful rocket I have yet measured.

While its peak thrust comes in ever so slightly below R-3 (which clocked in at 1061 grams), its total impulse is double most of my other motors, with R-3 being ‘only’ 5.13 Newton seconds, and having a very choppy thrust graph due to unstable and restarting combustion.

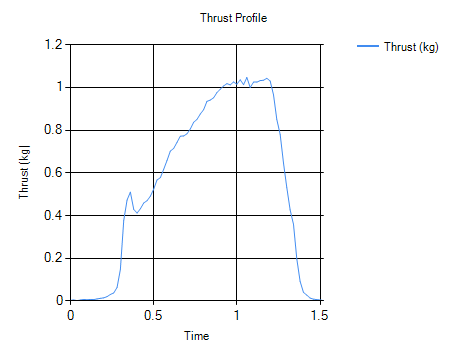

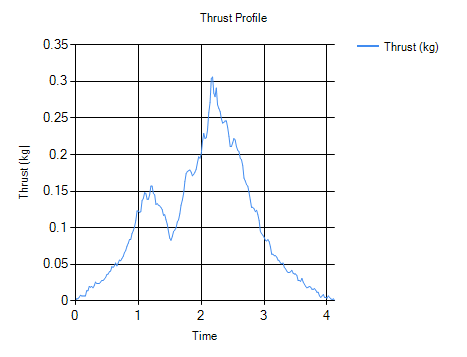

Speaking of which, the thrust curve of R-13 came out beautifully!

(of course generated by Impulse Calculator 2000)

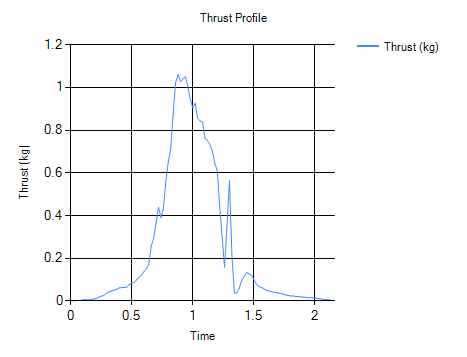

This is the graph of R-3 for comparison

And R-12 for good measure.

As you can see, in both power, burn time and consistency, R-13 performed exceptionally.

I have a few ideas as to why these results show such a drastic improvement.

First, the Type II igniter.

Which, while not actually mounted inside the motor, as was the case with BTIR-1 (, which with its R-11 motor showing unexpected performance inspired this test), still provided the anticipated effect and is the only difference between this test and the one of R-12.

The excellent performance, despite not actually being inserted into the motor, I predict to be because of the improvised fusing.

My hypothesis, is that after the igniter lit, it burned the fuse taped to its end, which, when it continued burning above where the tape was holding it together, fell down into the combustion chamber, igniting the motor instantly.

This is due to the hot gasses from the gunpowder pre-filling the engine with pressure and temperature, which encouraged combustion to such a degree the pressure quickly became self sustaining.

So, as is obvious in hindsight, the solution was more explosives.

Its ironic how the most rushed and improvised test so far resulted in the best results I’ve seen yet!

The plan now is, to make another 2 engines of the same design, and then test one of them with a Type II igniter to see if this performance can be replicated.

The second motor is then to be used, after having its performance predicted by its ‘brother’, in a BTIR type aerodynamic housing.

The performance and altitude profile of which would be pre-calculated from the performance of the previous test, assuming that 2 identically made rockets from the same batch should perform about the same.

And now, because I couldn’t find any other place to insert these organically, the pictures of R-13 post test.

As always, the raw data is provided both as backup, and so that anyone wanting to calculate all this for themselves can do so if they so desire.

(In a 7-Zip archive):

I also recommend Notepad++ for viewing and editing

All in all, not a bad day.