After a few days delay due to the holidays I launched rockets 3 to 5 on the improved STTS, which was modified to take readings 50 times per second instead of 10, and keep track of time internally to minimize data parsing necessary

First of course some videos (the fun part):

As you might have noticed rocket 3 does not have a main cam video to accompany it, this was due to it not recording…

This is also why there were two cameras

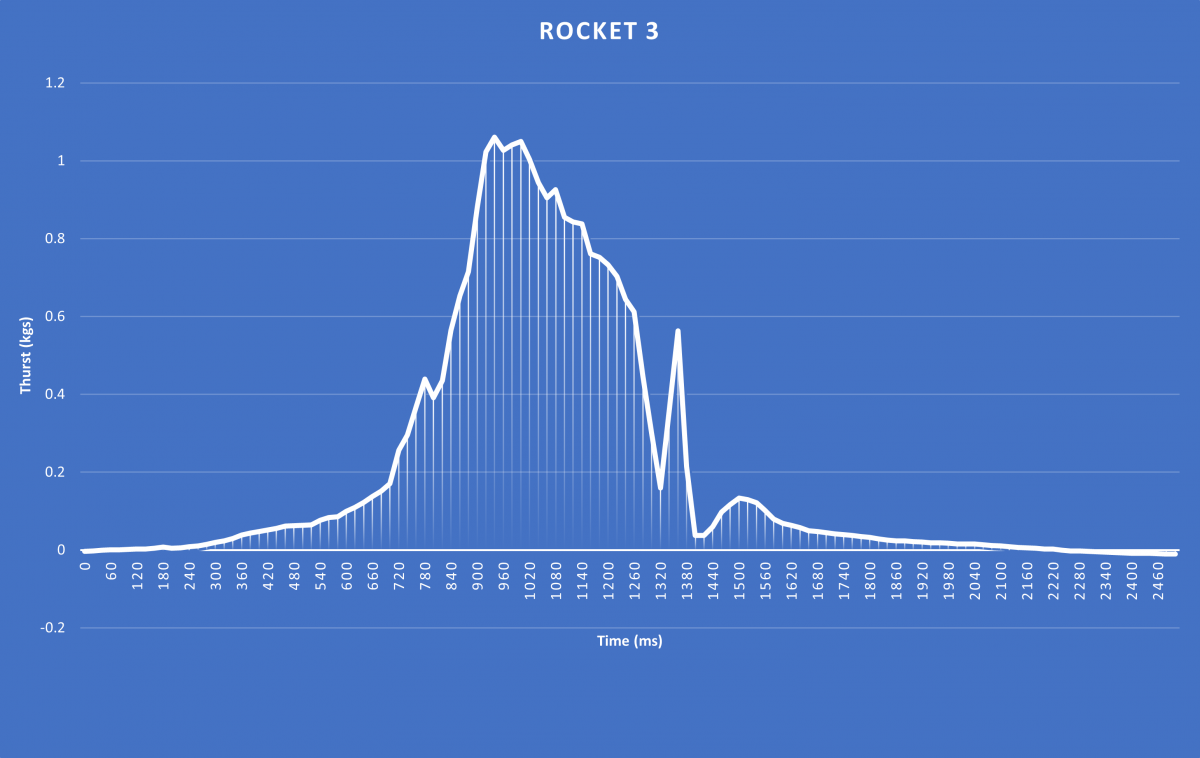

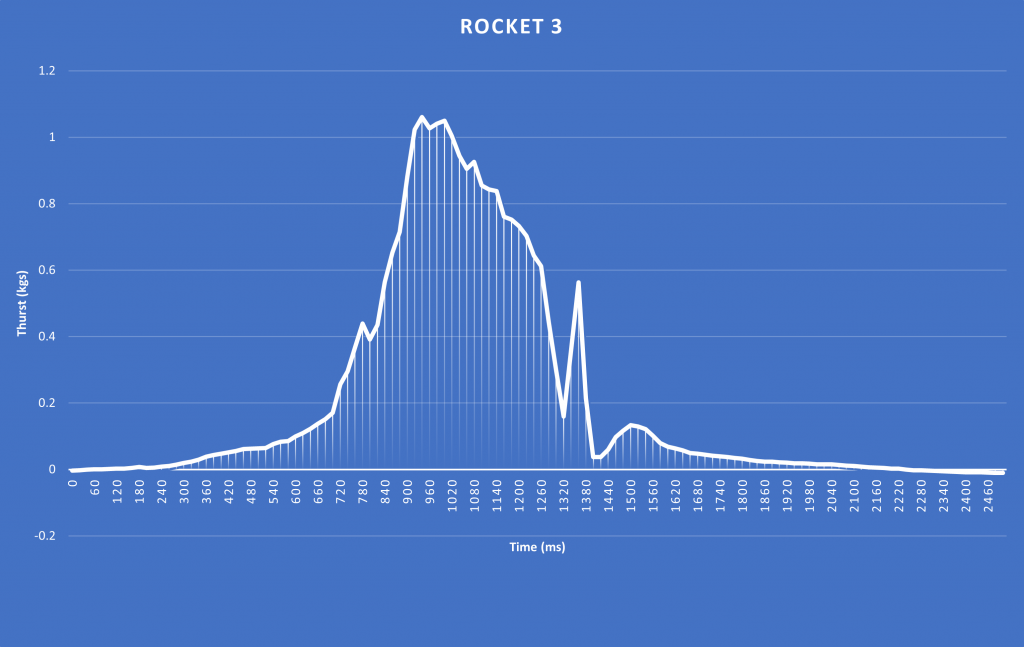

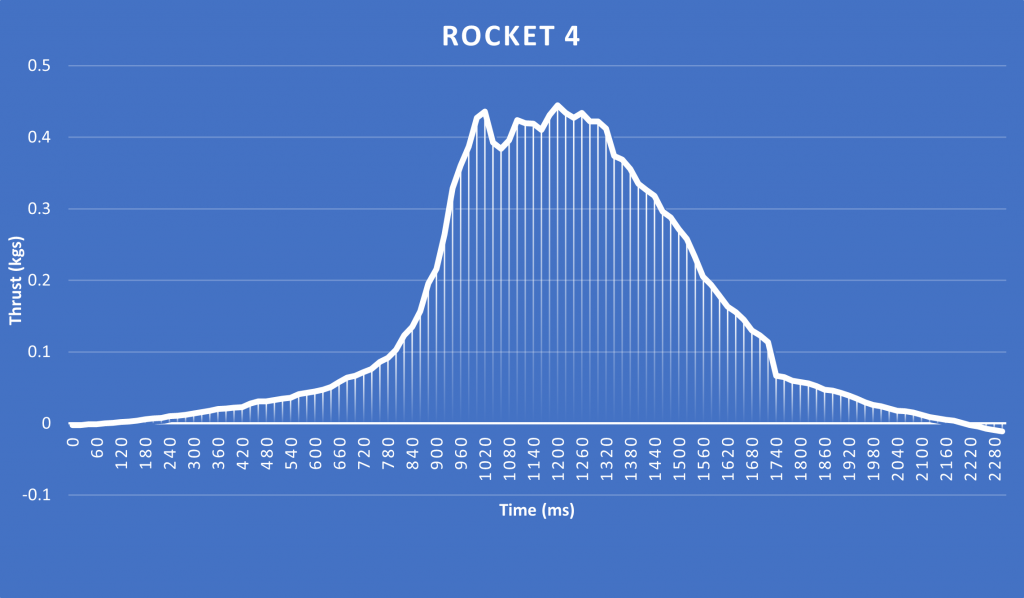

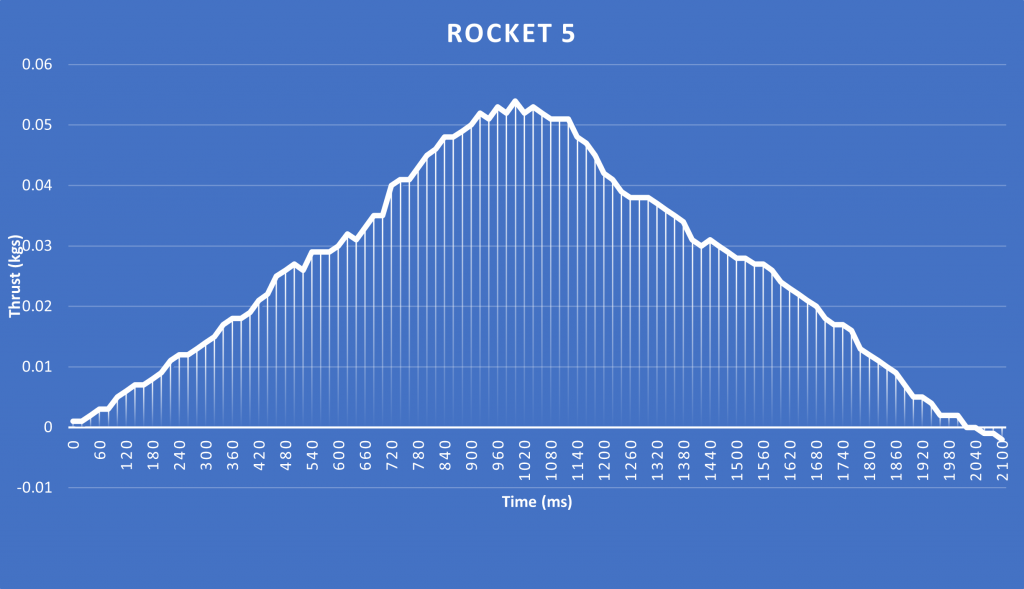

of course, the most important data here is the actual thrust, here are some graphs (data point text left out to allow for readability):

| Rocket 3 | Rocket 4 | Rocket 5 | |

| Peak Thrust | 1061 g | 445 g | 53 g |

| Burn Time | 0.9 s | 1.5 s | 1.9 s |

| Weight Before | 26.41 | 25.00 | 13.01 |

| Weight After | 10.69 | 10.17 | 6.39 |

| Weight Difference | 15.72 | 14.83 | 6.62 |

Rocket 3 is the first rocket to break the 1kg barrier, I think this is mostly due to the nozzle not blowing out due to slightly reduced performance / chamber pressure and a good bit of luck

The thrust spike at the end might be pressure releasing after a blockage cleared or the nozzle leaked from the sides, as visual cues might suggest

Rocket 3 pre-launch

This leads me to believe its pressure escaped from the side of the nozzle after the plastic deformed due to temperature

It could also be that this kept the nozzle intact, due to pressure venting from a different place (This side venting can also be heard on video as a sputtering sound)

I assumed this rocket would produce less thrust due to the increased nozzle diameter, which was a unintended side effect of the manufacturing process

However, probably also due to a manufacturing error and a bit of bad luck the nozzle was still blown out (you can see this as a smoke ring on the footage)

Rocket 5 performed worst out of the 5, which I think is due to a number of factors

for one, its half sized and thus had only half the fuel, secondly the pipe was ‘wonky’ to begin with probably resulting in the nozzle blowout

and the build quality was the worst out of the 5, so it was expected to perform badly

I was trying to produce a half size model for ‘hop tests’, where I can test a scale model of my rocket (for tuning parachute ejection systems and testing fins) without gaining appreciable altitude

I will try this concept again when my second generation casings are done (more on that later)

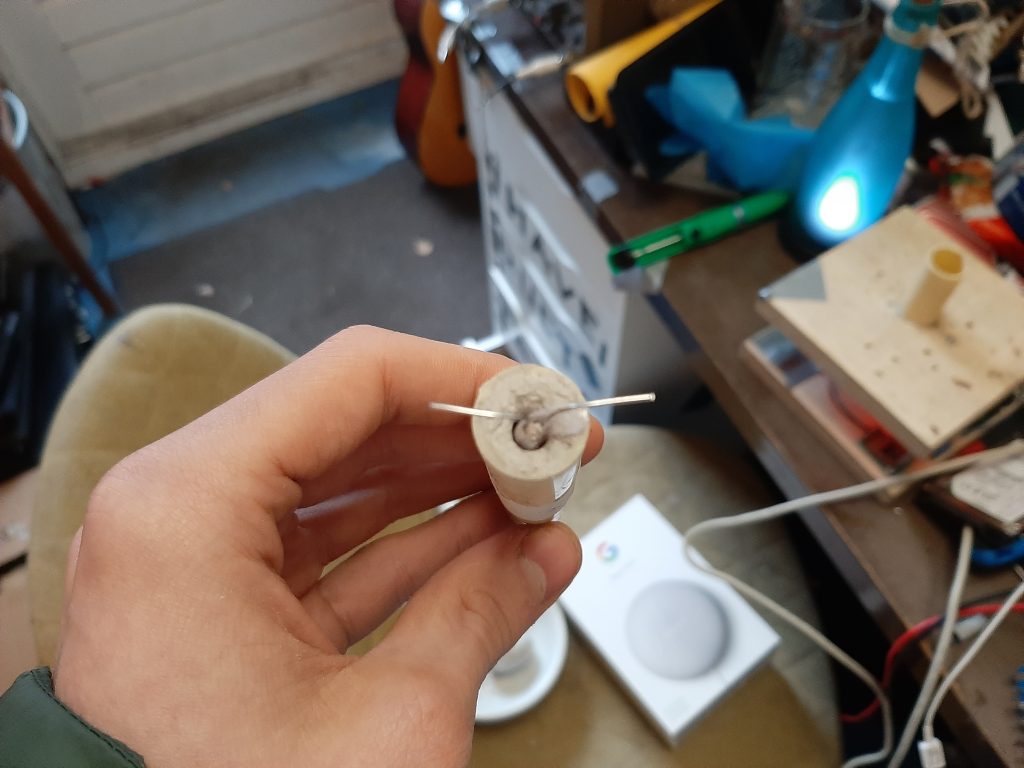

As for the ICBM and igniters, it performed incredibly well, igniting 5 out of 5 rockets without fail

When igniting Rocket 4 for example, there was a delay of only 0.5 seconds between the relays switching and the rocket igniting!

The Ni-Chrome wire also survived fine, with 3 to 5’s igniter wires shown left to right

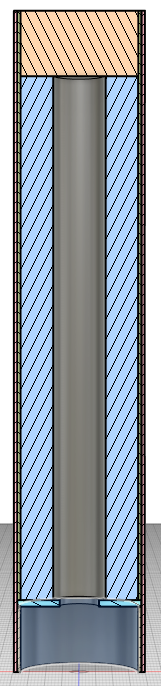

The next thing I want to do is build and test my new Casing 2.0 design

A 3d model I made of it is shown here:

It consists of 2 10cm lengths of pcv tubing (18 and 22 mm) nested around each other, with a clay bulkhead at the top, fuel in the middle, and a metal washer at the bottom held in place by a glued 1cm piece of 18mm pvc

The outer tube does 2 things:

1. it reinforces the casing, making temperature deformations and ruptures less likely to occur

2. it holds the smaller tube in place, allowing it to hold the nozzle in place

This has yet to be tested or made so only time will tell if its a reasonable design or not

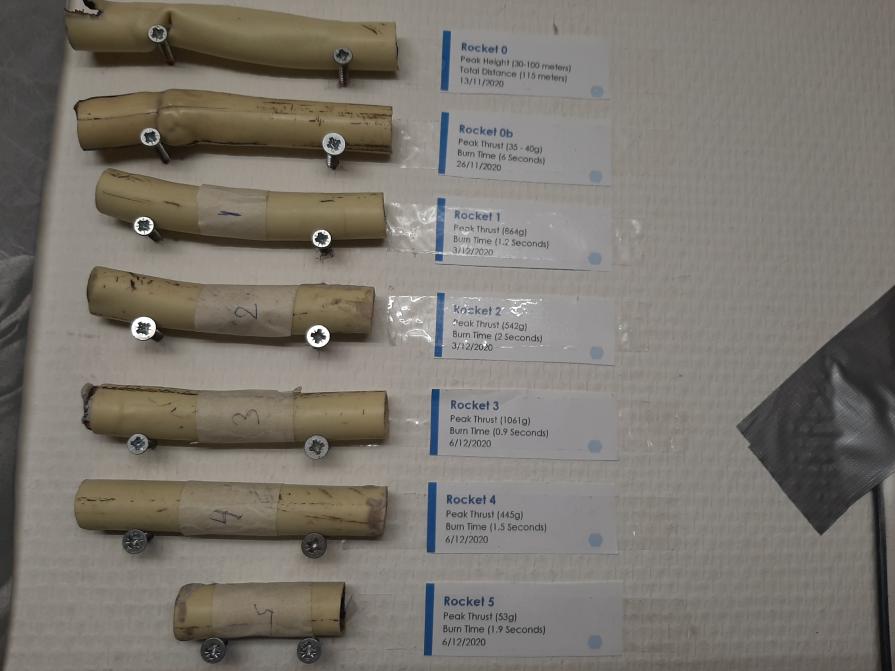

Almost all my recent rockets have also been mounted to my wall, next to my space pioneer tribute wall

I am going to need more wall at some point

I have also decided, due to the data not fitting into the graphs that I will be uploading my data from these and previous tests to the site right here, so you can look at them yourself if you want to

I might also do this for other resources such as 3d models, schematics and uncut / uncompressed videos as well

do Contact me if you want to ask anything specific

(Its in 7-zip format due to WordPress not allowing .zip files, 7-zip can be downloaded here)

That’s all for now