After some consideration and experimentation it was decided that a cast concrete nozzle might be better than a bare washer going forward

R-8 was made to test our cast gypsum nozzles, and is the first test to be conducted in 2021

First some information about the nozzles:

Since concrete was not available gypsum was used, which was cast into 3d printed molds covered with a small layer of Vaseline to aid in separation

These molds were also designed in such a way as to allow a small metal washer to be placed on them, while still allowing the mold to be removed from the bottom without getting stuck

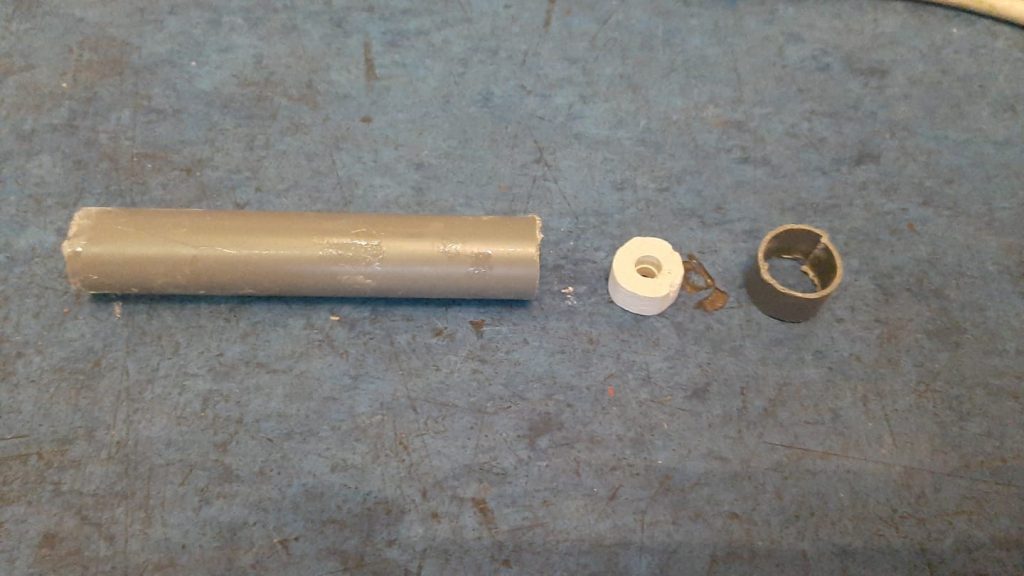

Mold with and without pipe

Mold with washer

A total of 8 were cast, 4 with rings and 4 without

They proved tricky to remove due to a slight expansion holding them in the tube and a high fragility

This resulted in only 2 getting out in one piece (of which one broke while mounting), and the ones with the rings to be discarded due to them not binding to the metal or having enough spare room to fuse around it

This and the results of the test have made me stop considering gypsum, so concrete will be acquired and some testing will be done with composites of gypsum and binder

R-8 after fuel casting (note that the length of the fuel tube was reduced by 1cm to facilitate the increased height of the nozzle)

As for the test itself:

| R-8 Without Fuel | 16.80 g |

| R-8 With Fuel | 30.04 g |

| R-8 Fuel | 13.24 g |

| R-8 Fully Assembled | 35.30 g |

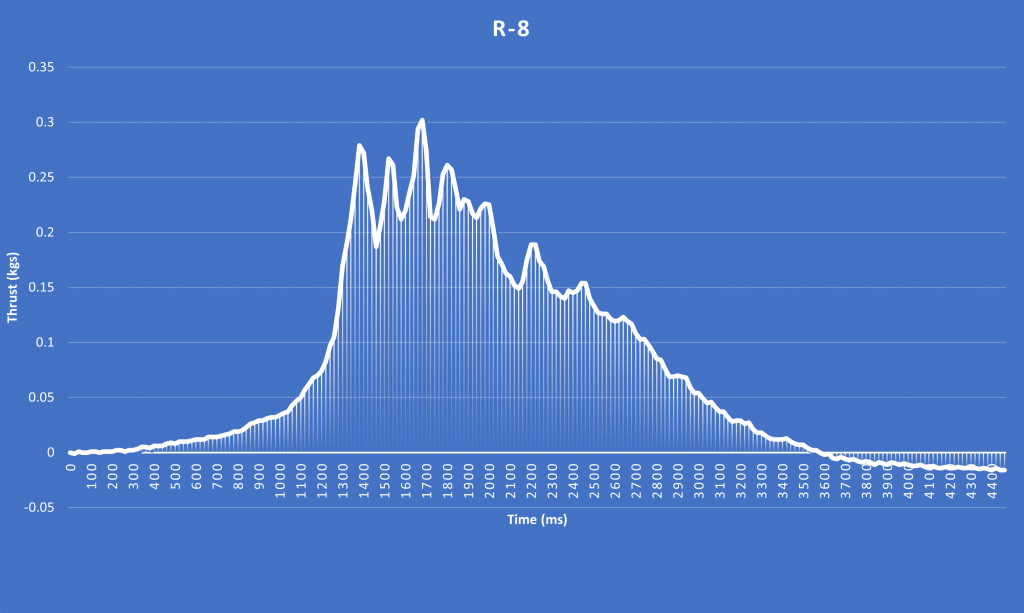

| Peak Thrust | 308 g |

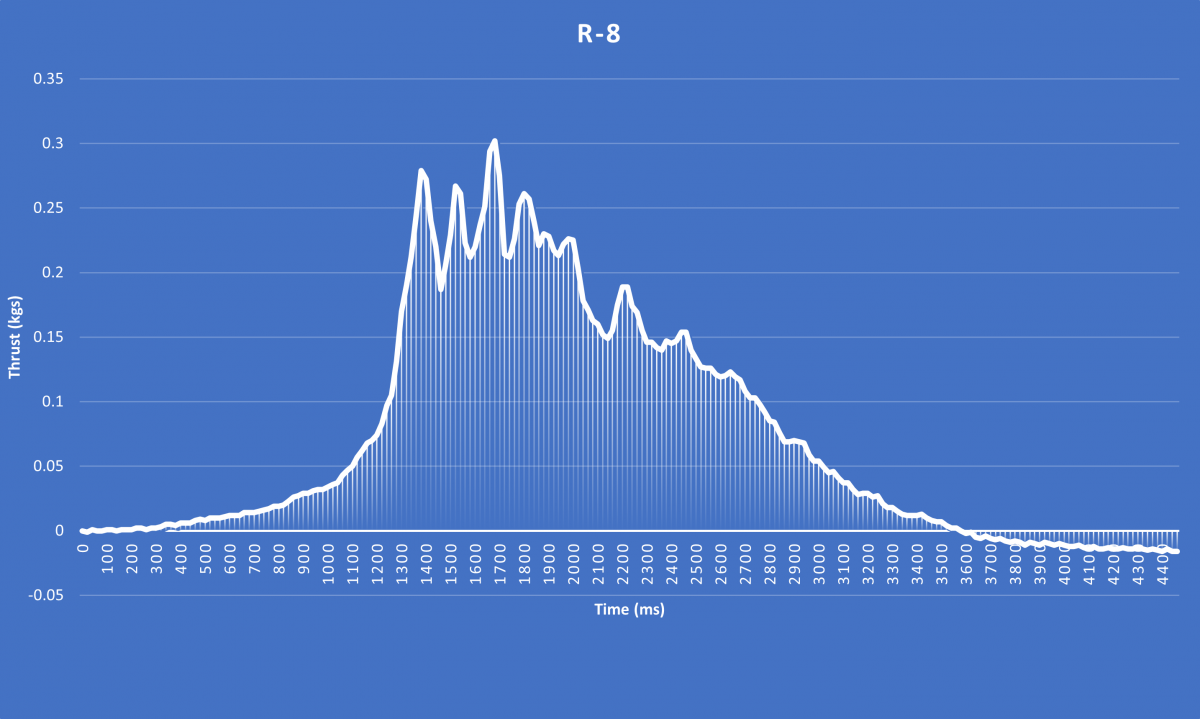

As you can see from the flame profile and the peak thrust the nozzle failed substantially

It did not blow out, as a clay nozzle might, but it did ablate away very quickly, increasing the throat diameter to the point of uselessness

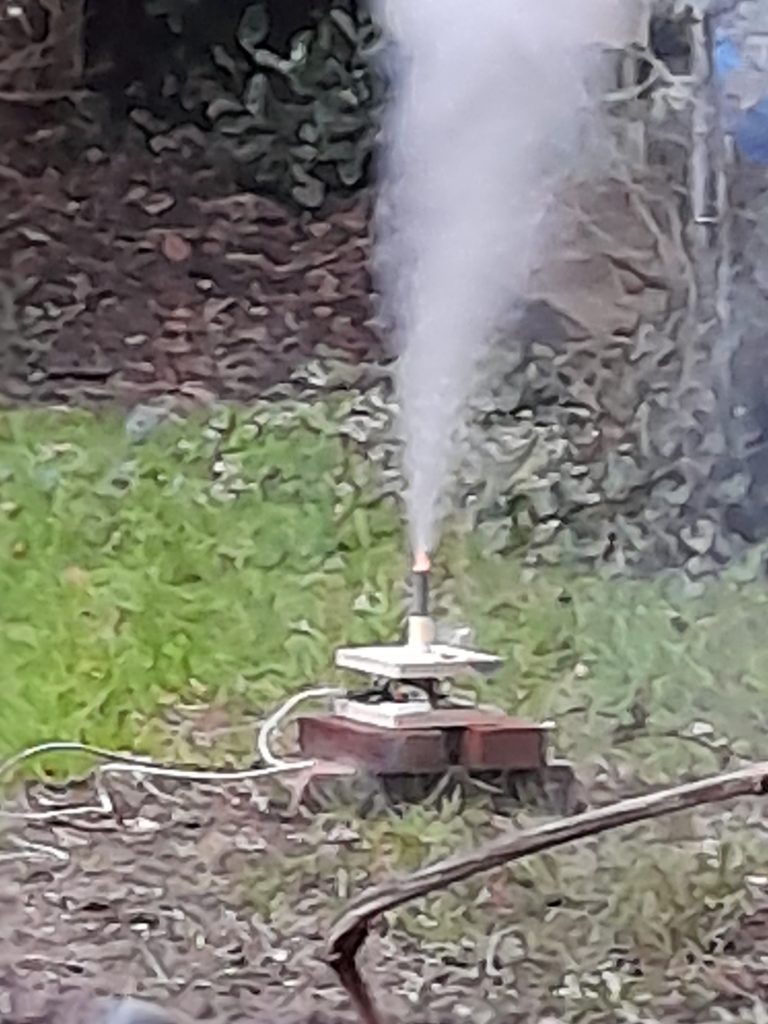

Picture of R-8 in action provided by my grandpa who was attending the test (Thanks!)

Another problem which occurred -unrelated to R-8- was that due to the 2 ICBM-B alligator clips shorting during the first ignition attempt relay 2 broke, requiring some field rewiring to resolve

The battery luckily seems to still be fully functional and the only functionality that is now missing is the continuity light, this will be fixed before the next test (as of R-9 this is yet to be fixed, and no plans have been made on how and when to fix this issue)

As always, the raw data (In a 7-Zip archive):

I also recommend Notepad++ for viewing and editing

Next step is improving the nozzle design, using a different mixture and maybe using smaller washers to allow for better structural integrity

I also made a lot of small tweaks and improvements to various things, which have been posted in a different article, which can be found here

2 thoughts on “R-8 Test Results”