After a short Christmas break, testing resumed on the casing 2.0 design

Main iterations for this test are:

- Better Fitting Nozzle Washer

- Better Glue Application And Tolerances

- Better Cast Fuel

These changes allowed R-7 to survive the burn with the nozzle in place, but moved the failure point to the side of the casing

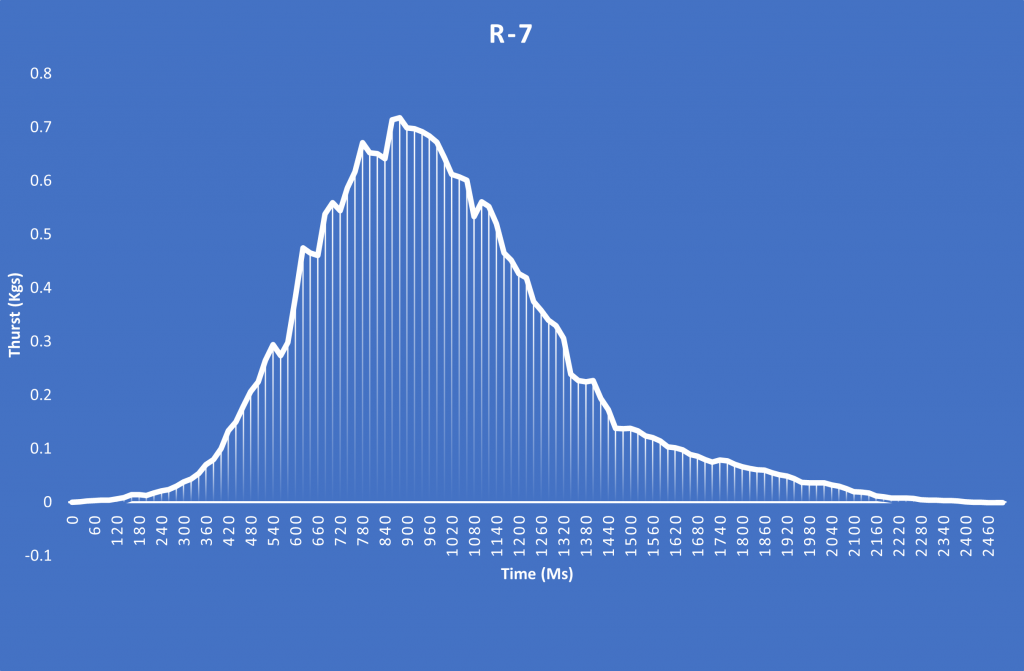

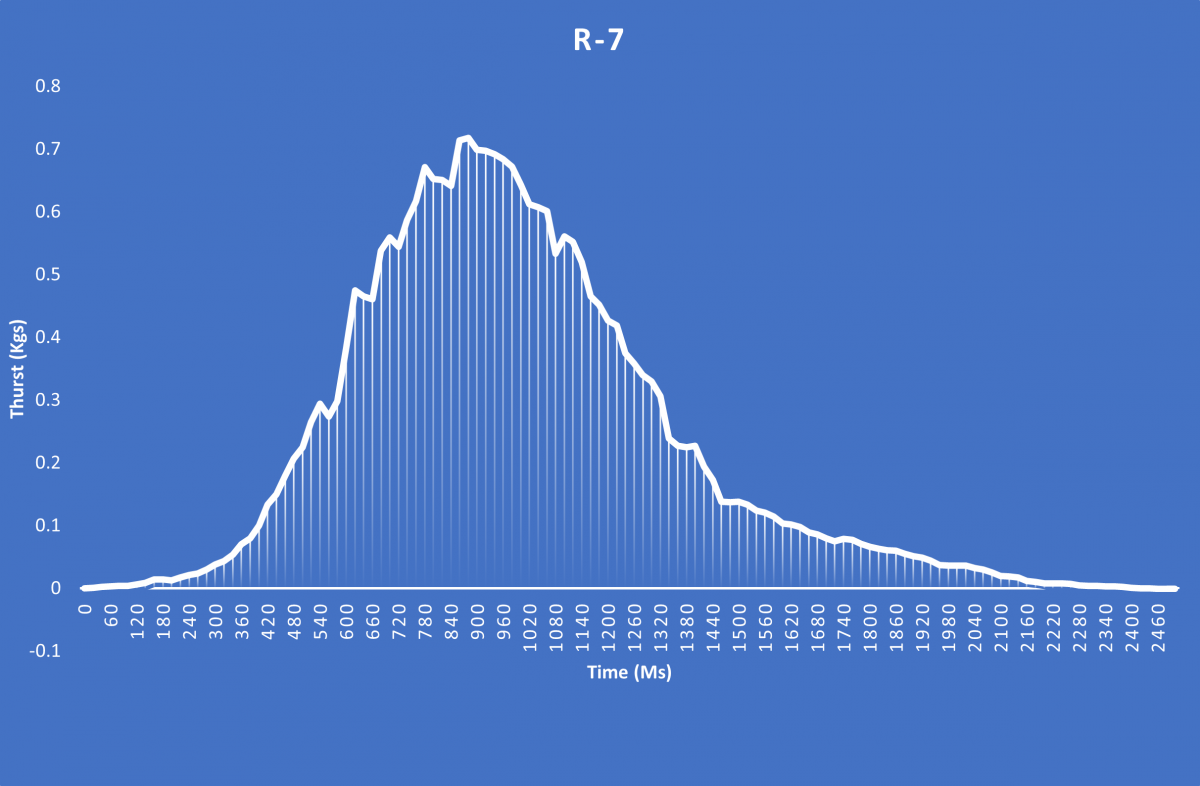

| Test Date: 28/12/2020 | |

| Pre-Test Weight: 38.74g (With igniter) | |

| Post-Test Weight: 20.21 | |

| Peak Thrust: 718 g | |

| Burn Time: 2 Seconds |

As you can see there was a minor structural failure on the casing, resulting from pressurized flames under the nozzle finding a different path trough the 2 layers of PVC

A solution for this might be a different case material, not design

Possible materials include: Fire Retardant Cardboard or Aluminum (Aluminium)

Further Research Is Needed

(The naming scheme of the rockets has also been changed from R* to R-*, I did this by accident but I think its quite cool so I’m keeping it)

I have also acquired a 3D printer (A Creality Ender 3 V2 to be precise), and have been experimenting with 3D CAD Design

Notice the grey ring around the rocket on the STTS, this is a custom designed and printed part that makes sure the rocket does not wobble during testing

(The small holes are for venting potential casing leakage and are intentional)

I intend to make much if not all of the main rocket body from this

Stress Testing shows it can handle a lot of physical impact force

It is great to be able to design and develop a part in half an hour instead of days

I also got a old phone from a relative (Many thanks), and have repurposed it into a wrist mounted PDA of sorts, using a 3d printed brace

I am using this as a pre launch / test checklist and it helps tremendously with organization and efficiency

It still needs some work with the mounting system, but that can be ironed out

I am also hereby setting a goal:

If / When I manage to make 5 Rocket Motors that behave in much the same way (Thrust profile, max power, burn time) and produce a minimal thrust of 500 g, I will focus my efforts on launching 1 up in a (probably 3d printed) rocket

I hope to achieve this early to mid 2021 (I was oh so optimistic back then)

As always, the raw data (In a 7-Zip archive):

I also recommend Notepad++ for viewing and editing

4 thoughts on “R-7 Test Results”