So, a while ago, I stumbled upon a document.

(which I downloaded from here)

Its by the American Department of Defense Food Engineering Services Team, And it details the precise specifications, procedure and test standards for Chocolate Brownies.

These are not just regular brownies, these are shelf stable vacuum packed brownies made for MRE’s (Meal, Ready-to-Eat), designed to be left in a warehouse (without climate control) for multiple years and still be ‘Edible’.

Now, this document outlines the procedure as it is for a factory producing thousands of these at a time, but this wont stop me of course.

And it hasn’t, multiple times.

In this write up I intend to document my second attempt to bake these “Military Brownies”, and what I have learned from doing so.

First of, the recipe is defined in “Parts by weight”, which is great if you have a giant freezer filled with liquid Egg, as defined by section 3.2.6:

Whole eggs, liquid or frozen.

Whole eggs may be liquid or frozen and shall have been

processed and labeled in accordance with the Regulations Governing the Inspection of Eggs and Egg

Products (7 CFR Part 59).The whole eggs shall be egg whites and egg yolks in their natural

proportions as broken directly from the shell eggs as evidenced by a USDA Egg Products Inspection Certificate.For liquid whole eggs, the USDA certificate shall state the date and time of pasteurization. Liquid whole eggs shall be held at a temperature of 40°F or lower and shall be held for not more than 72 hours from the time of pasteurization until the start of formulation of the product in which they are used.

Frozen whole eggs shall be held at 10°F or lower and used within 120 days from the date of production. The whole eggs shall be free from off-odors and off-flavors, such as

Section 3.2.6

sulfide-like, fruity, sour, musty, or metallic, and shall be free from foreign materials.

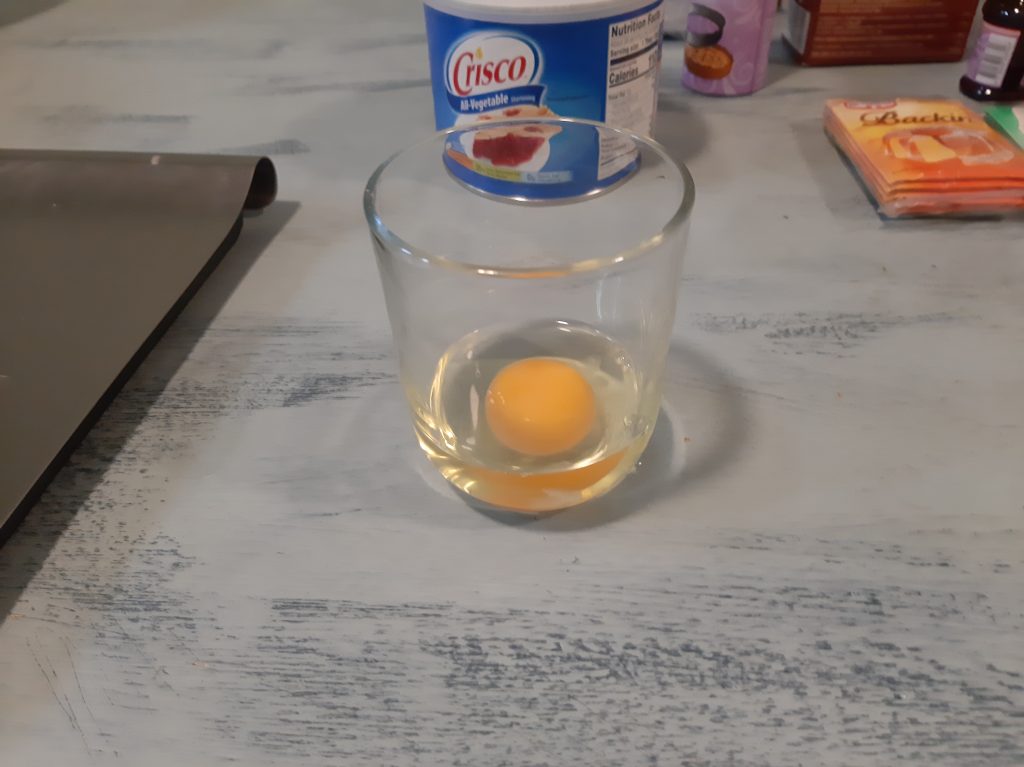

But, I don’t actually own a freezer filled with Egg, let alone Egg following these specification, so I had to improvise and adapt.

I had to do this of course, since while almost all ingredients are packaged in such a way that allows precise and variable amounts of them to be dispensed at a time, this can not be said for your average grocery store Egg.

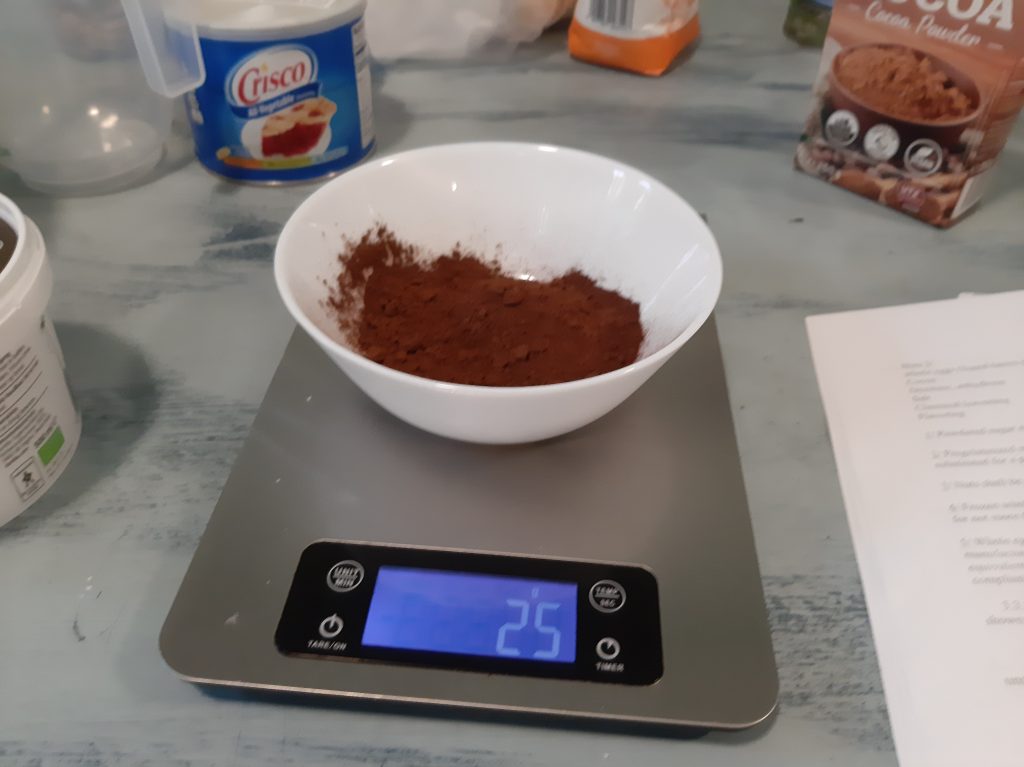

So, before starting with the baking, we first measured the weight of a single Egg.

This turned out to be 52 grams, and all other amounts were based off and calculated from this value, since it was the only variable we had minimal control over.

After calculating how much of each ingredient would be required for 2 Eggs worth of brownies, work proceeded in actually baking.

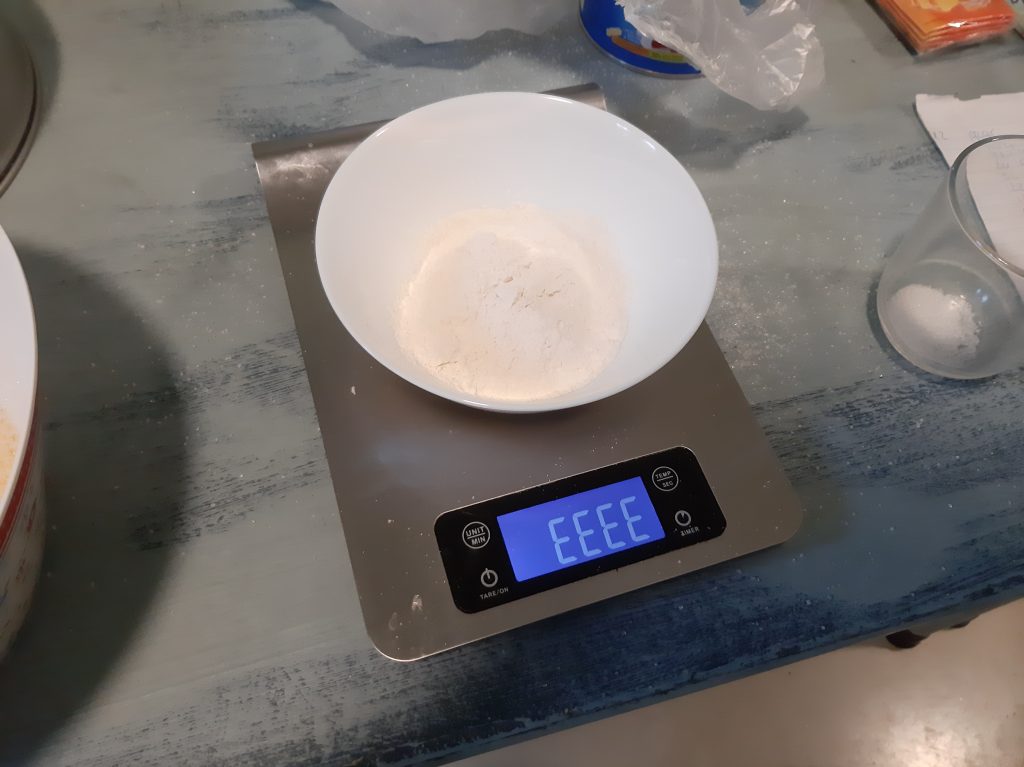

This turned out to be harder than expected, mostly due to a unexpected and unexplained temporary failure of the scale, which out of nowhere started screaming at us.

But luckily, after some basic troubleshooting (namely turning it off and then back on again, repeatedly) it started doing its one job and I could finish measuring the flour.

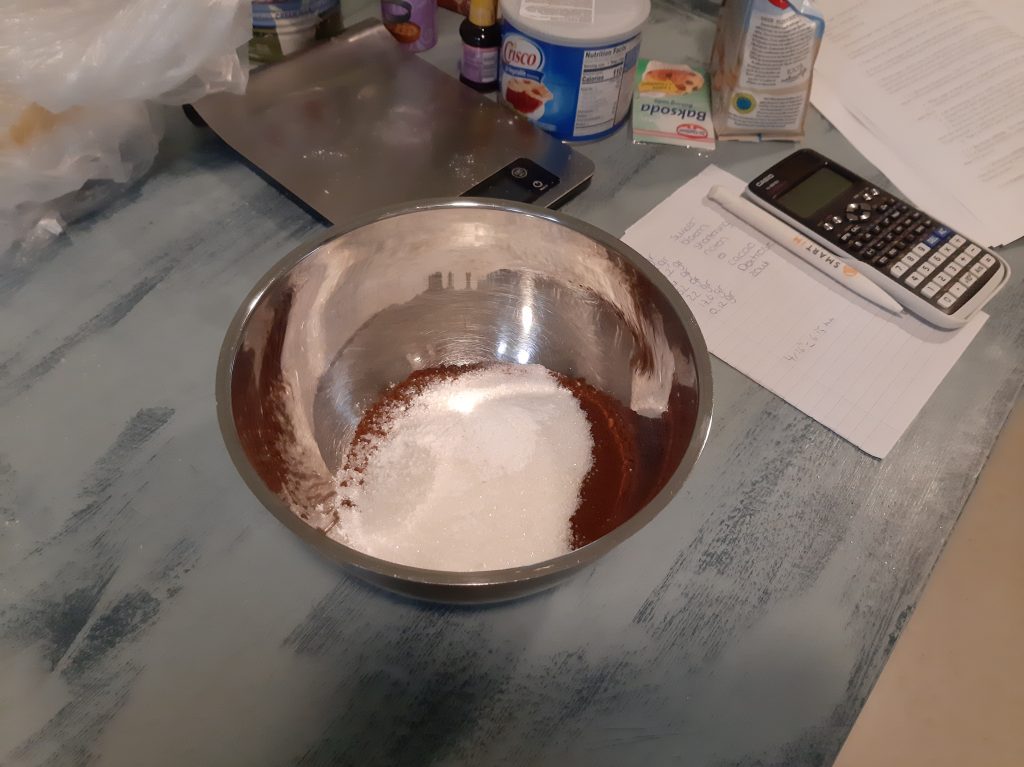

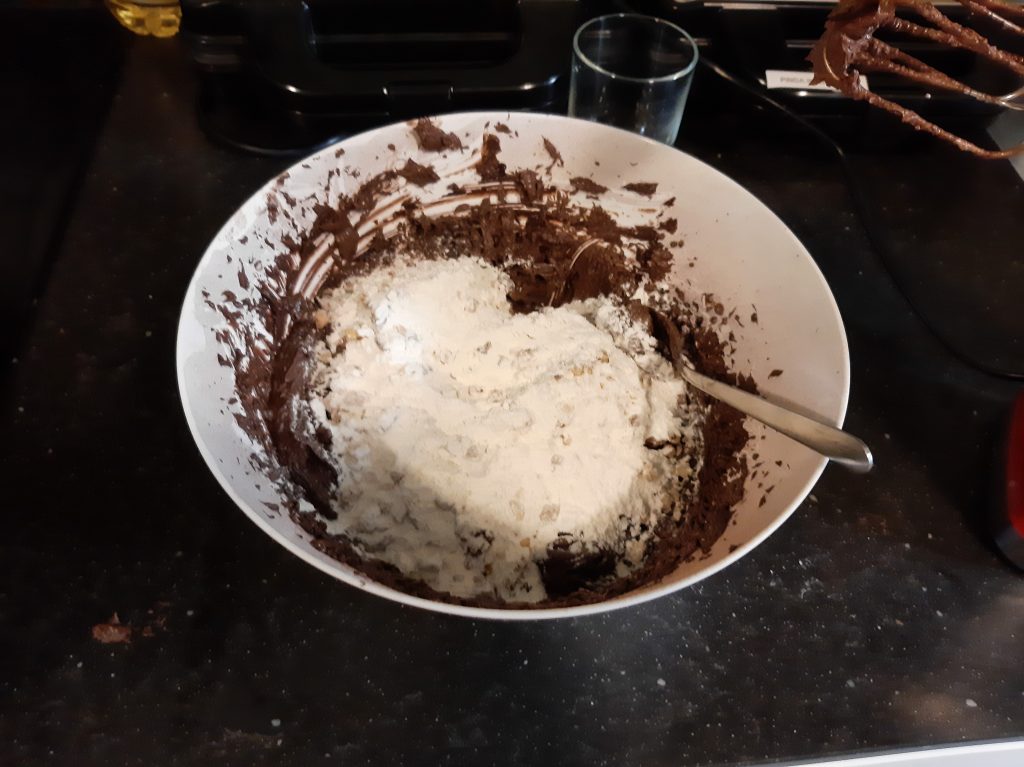

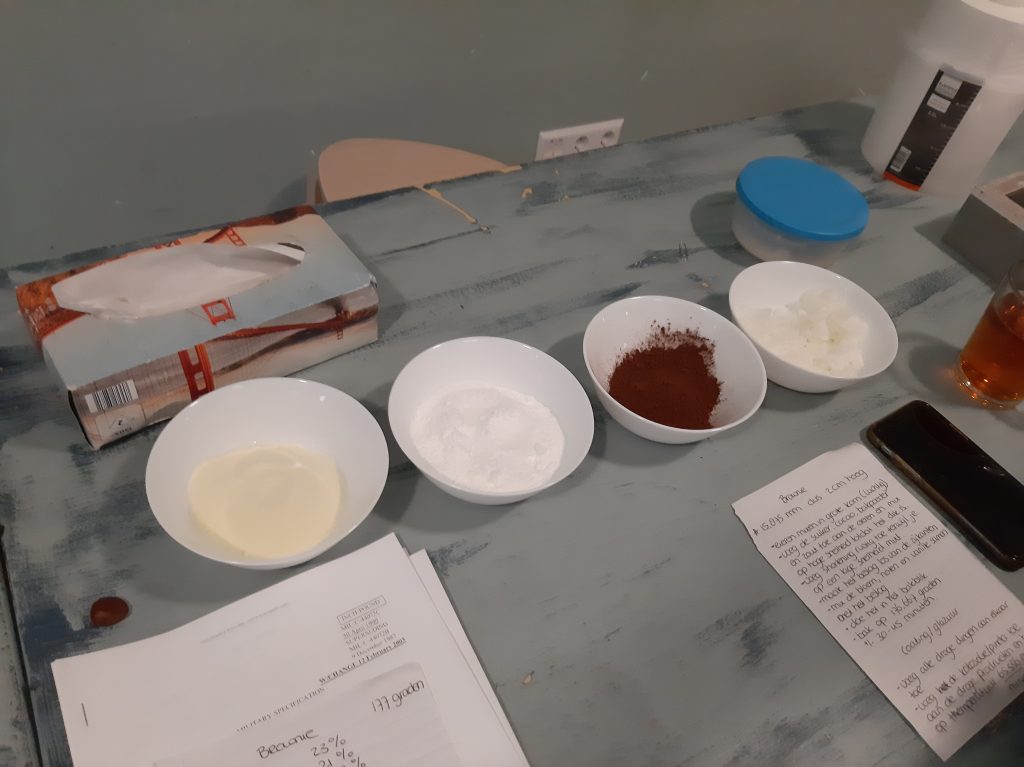

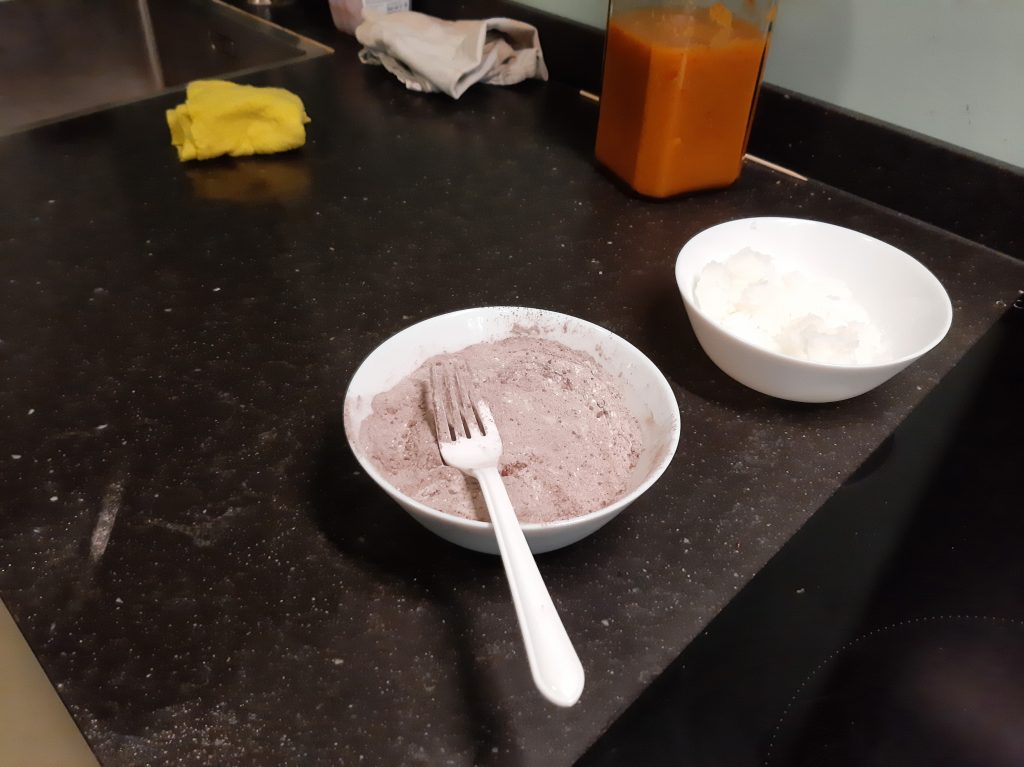

Then, the dry ingredients specified in the document were added together in a bowl as prescribed.

Then, the two Eggs were “Whipped in large bowl on high speed until light and fluffy.”, as described in Section 3.3.2 Subsection a.

Then, the dry ingredients were added to the Egg, and then they were “Whipped on high speed until thick.” as specified in Section 3.3.2 Subsection b. (sensing a pattern yet?)

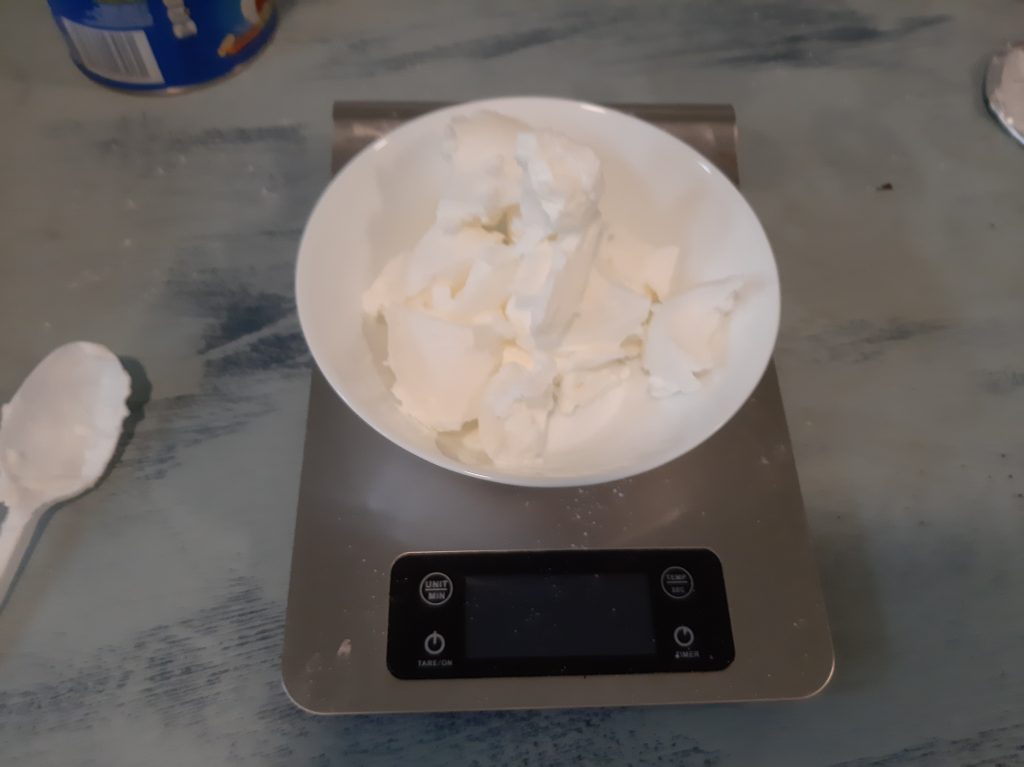

Now, Shortening.

Shortening is defined in the manual under Subsection 3.2.4 as:

Shortening, hydrogenated.

Shortening shall be a refined, hydrogenated vegetable oil or combination of refined vegetable oils which are in common use by the baking industry. Coconut and palm kernel oils may be used only in the coating.

The shortening shall have a stability of not less than 100 hours as determined by the Active Oxygen Method (AOM) in Method Cd 12-57 of the Commercial Fats and Oils chapter in the Official and Tentative Methods of the American Oil Chemists Society.

The shortening may contain alpha monoglycerides and an antioxidant or combination of antioxidants, as permitted by the Federal Grain Inspection Service (FGIS), and the

Subsection 3.2.4

Federal Food, Drug, and Cosmetic Act and regulations promulgated thereunder.

(Fun fact: The previous batch of brownies was positively ruined by multiple factors, one of which was not noticing the line “Coconut and palm kernel oils may be used only in the coating.“.

Which resulted in the (mostly raw) brownies tasting excessively, even almost entirely, of nothing but Coconut, which while I like Cocos, most of everyone else does not, making other people not even want a taste.

Oh, and they didn’t taste like brownies, cause the Coconut Oil.)

Either way, Shortening is a thing in, like, America, and basically nowhere else.

So, since I do not live in America, I thought this would make it practically impossible to follow this recipe, since it would be impractical to get shortening.

Somebody apparently imported it into our country, and its sold at regular grocery stores.

Score!

Personal Comment: it looks (and feels) like that stuff you use to plug holes in walls, and not like something edible.

This was then added in, “While mixing on low speed.”, like mentioned under Section 3.3.2 Subsection c.

The result of Section 3.3.2 Subsection d. “Scrape bowl and whip on high speed until thick”, was the following product:

Then, a selection of nuts was prepared.

These are defined under Section 3.2.5:

Nuts, walnuts, shelled.

Shelled walnut pieces shall be of the small piece size classification, shall be of a light color, and shall be U.S. No. 1 of the U.S. Standards for Shelled English Walnuts.

A minimum of 90 percent, by weight, of the pieces shall pass through a 4/16-inch diameter round hole screen and not more than 1 percent, by weight, shall pass through a 2/16-inch diameter round hole screen.

the shelled walnuts shall be coated with an approved food grade

Subsection 3.2.5.3

antioxidant and shall be of the latest season’s crop.

Well, we didn’t have a 4/16th and 2/16th inch screen, nor did we have the time to actually filter nut shavings, so it was decided to just cut them really small using a standard cutting implement (aka knife), eyeballing their size.

The result was this:

So this was added to the flour and flavoring agents, and then folded into the batter as defined by subsection something or other, you know the drill by now.

Then, mixing commenced.

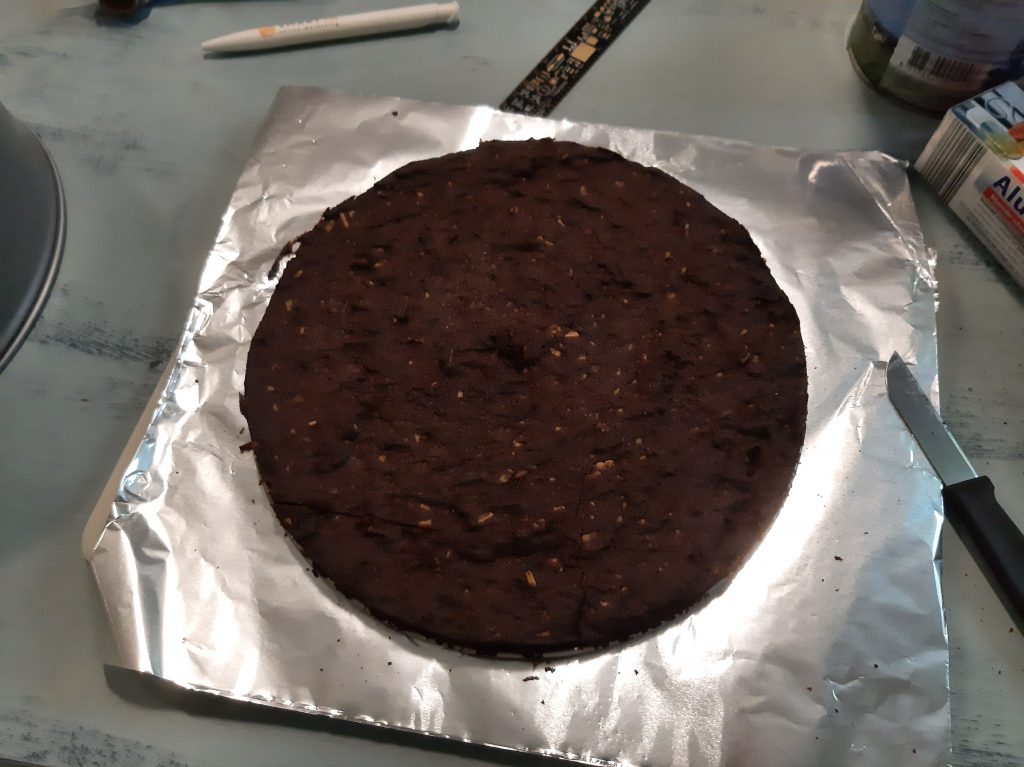

And finally, the batter was poured into its tray, and then placed into the oven.

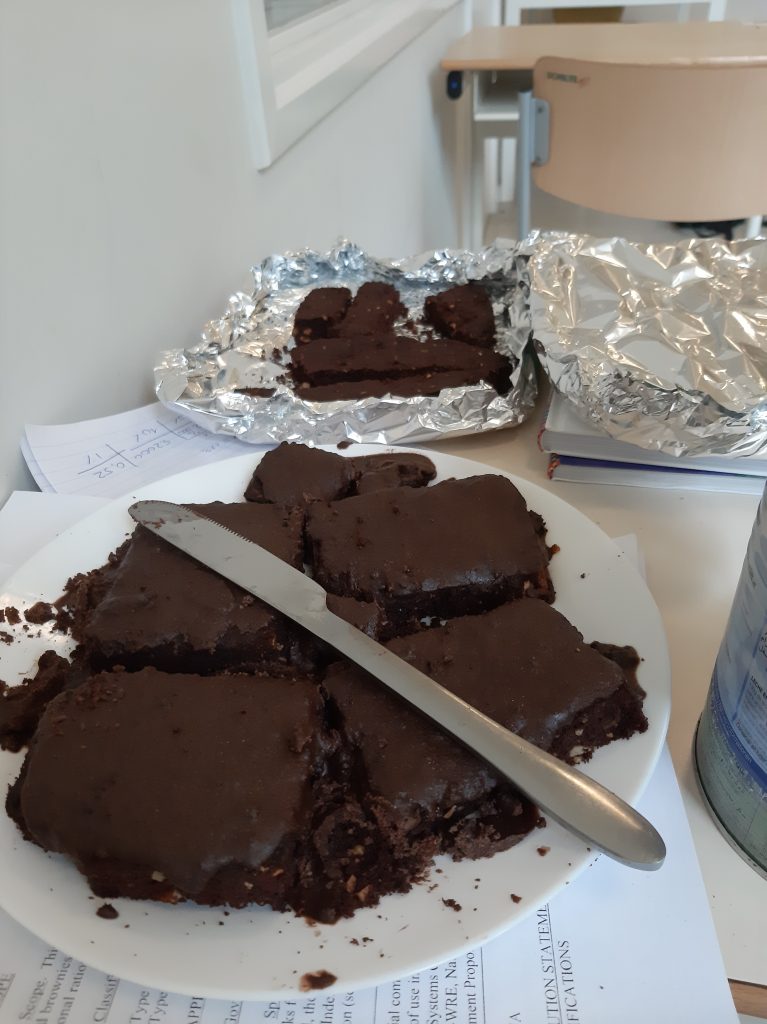

Then, when baking had finished, it was time for the coating.

Now, since these are military rations designed to withstand temperature extremes, you are faced with a problem.

How do you make sure the chocolate does not melt when stored in a hot warehouse, and spoil any chance of getting it out of the packet.

The answer is specialist chemicals of course!

That and not actually using chocolate.

The coating is actually a mix of cacao, dried milk, fat, sugar, and Polyoxyethylene (20) sorbitan monostearate.

Polyoxyethylene (20) sorbitan monostearate is not actually sold in regular grocery stores, so it was left out.

As for the preparation, this is what the doc has to say:

Chocolate coating preparation.

The formula for chocolate coating shall be blended on a dry-solids basis. Sorbitan monostearate and polyoxyethylene (20) sorbitan monostearate shall be melted, mixed with the added fat and the dry-solids blend and brought to a temperature of not less than 150°F.

The mixture shall be held at that temperature or higher for a period of at least 30 minutes.The coating shall be refined (20 microns or less, 7/10,000 inch) so that is has a smooth mouthfeel

without grittiness.The coating shall be such that, when the vacuum packaged product (at least 72 hours after manufacture) is held at a temperature of 1000 F for two hours, the product can be easily

removed from the bag without loss of coating. The product shall be allowed to cool at a temperature between 40°F and 70°F, for resolidification to occur, for approximately one hour prior to performing the test.The chocolate coating shall be Salmonella free (see 4.5.1.4).

Section 3.3.11

Leaving out the sorbitan simplifies the procedure at the cost of authenticity.

As for fat, coconut oil was used.

This was also defined in the document:

Fat.

Vegetable fat for the chocolate coating shall be natural or hydrogenated coconut, palm kernel, babasu, tucum, or other high lauric acid oils or mixtures thereof, or a mixture of one or more

of these which not more than 25 percent hydrogenated peanut oil or cottonseed oil, or both combined.The fats shall have a minimum stability of 100 hours when measured by the active oxygen method

(AOM).

They shall retain satisfactory odor, flavor, and color after heating to a temperature of 400°F.

The free fatty acid content shall be not greater than 0.08 percent prior to the addition of an antioxidant mixture or 0.1 percent after the addition of antioxidant mixture A, B, C, D, or E specified in 3.2.19.1.The moisture and volatile matter shall not exceed 0.1 percent after the addition of antioxidant mixture A, B, C, D, or E. The fat shall be adequately protected against oxidative rancidity, at time of manufacture or by the processor, by the addition of 0.1 percent by weight of an antioxidant mixture specified in 3.2.19.1.

Section 3.2.19

So, after assembling all ingredients, the mixing could commence.

We ended up adding more coconut oil, since it did not become liquid enough to pour over the brownies.

This might have something (or even a lot) to do with the absence of a 20 micron sieve.

Since we basically added non soluble powders into an oil, without a emulsifier or anything else really, it ended up being a suspension, a really really grainy suspension.

What I’m saying is it was more of a chocolate flavored sand than anything.

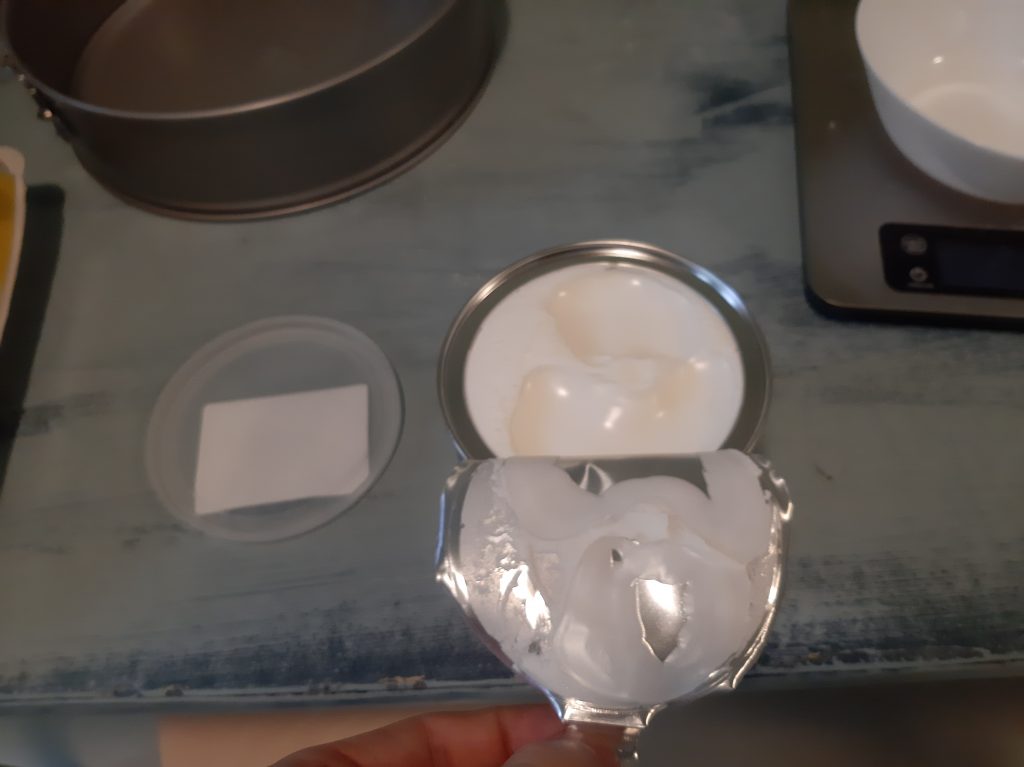

Another thing of note, is that before re-solidification had a chance to occur, it went kind of Non-Newtonian / Super Saturated on me, which had the practical upshot of it turning “more liquid” upon being prodded, as demonstrated here.

This has absolutely zero relevance to the actual brownies, but I thought it was kind of neat.

Meanwhile, the oven finished.

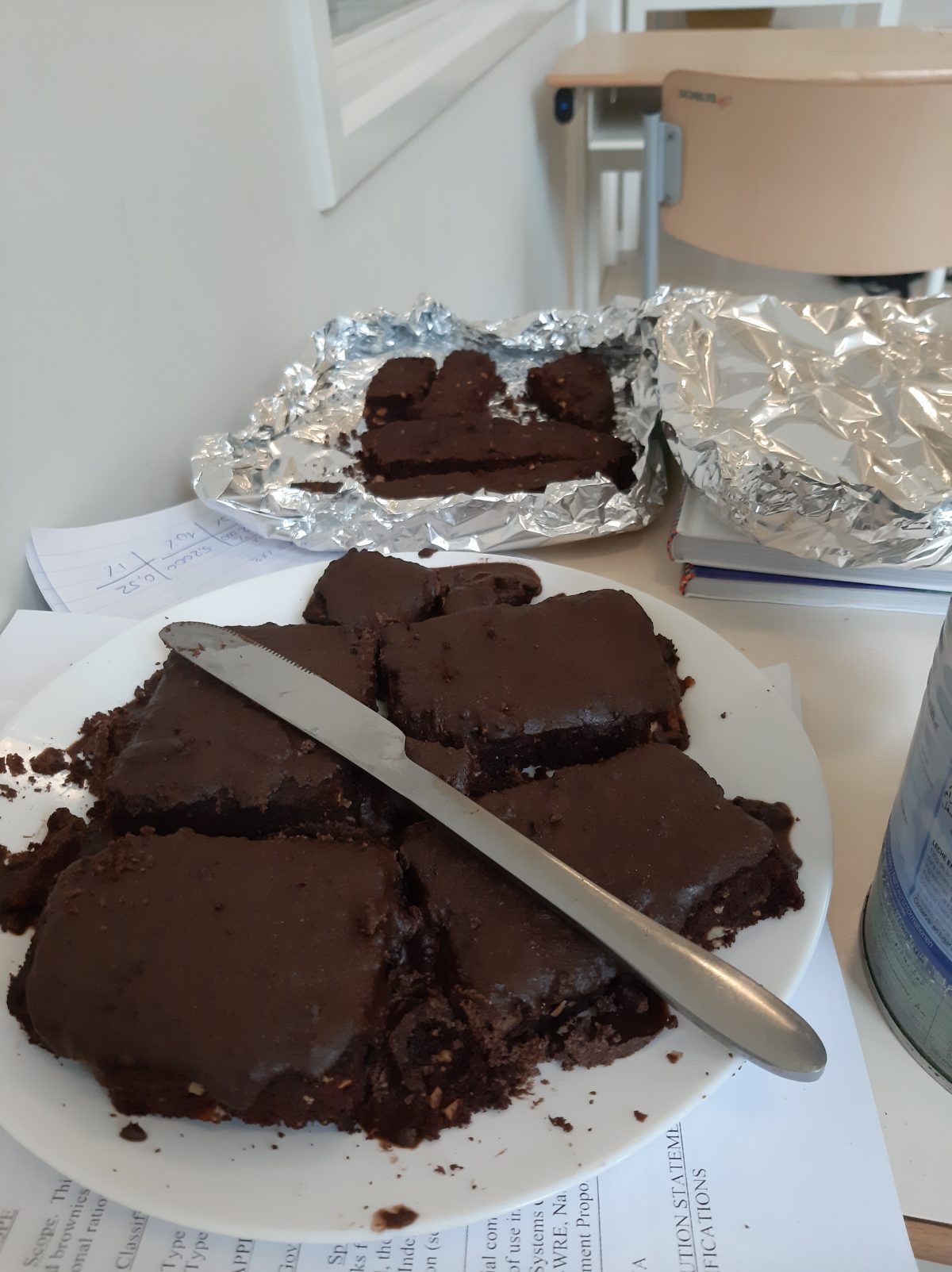

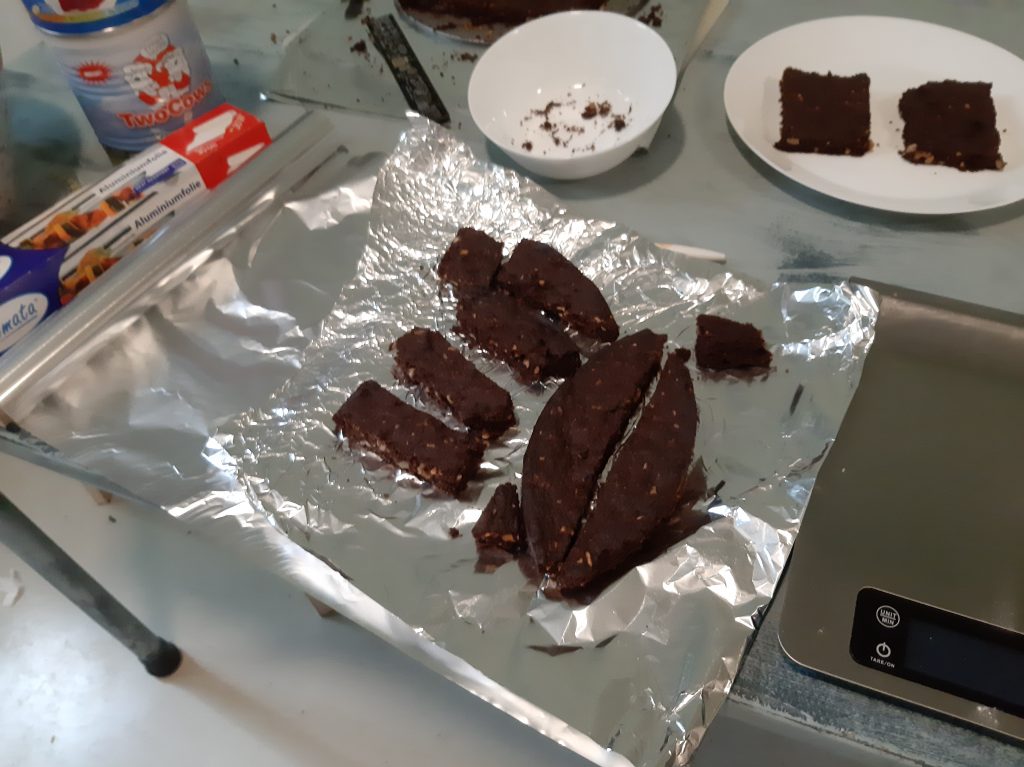

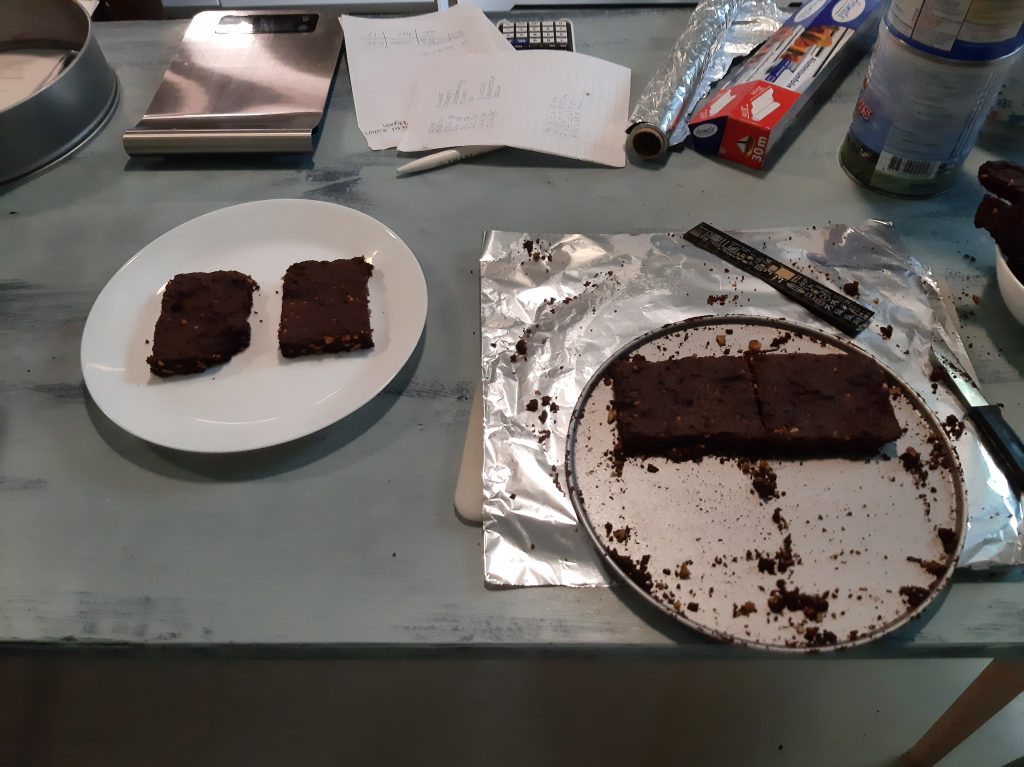

These were cut to shape, as defined in Section 3.4 Subsection f.

The dimensions of the coated brownie shall not exceed 3-1/2 inches by 2-1/2 inches by 5/8 inch.

(6,35 cm x 3,81 cm x 1,5875 cm)

As for the final product, the brownies without the chocolate coating, while very dry and crumbly, were very tasty and tasted like regular brownies (which was not expected)

The coated brownies, while not disgusting, were described repeatedly as weird and unusual.

Overall I think this was a great success!

If I ever do this again I would throw the coating powder mix into a blender to rid it of its “gritty mouthfeel”, and maybe try to find some of the chemicals to accurately make this.

That’s it, stay tuned for a (attempt at a) rocket launch at Thursday, with the maiden flight of BTIR-1!